[Selected] EPS foam building module equipment motor_foam molding machine maintenance is relatively simple

by:Veinas

2021-08-15

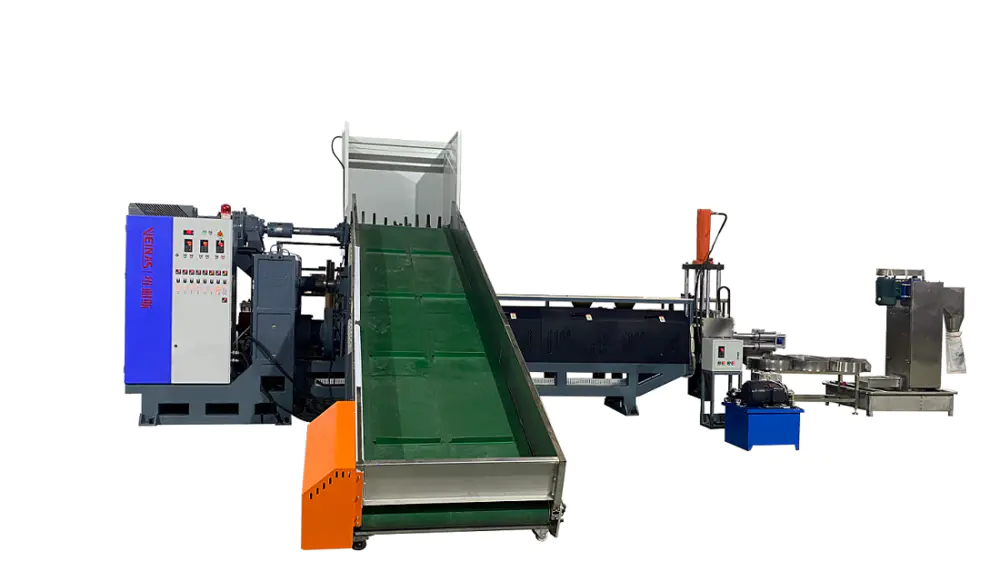

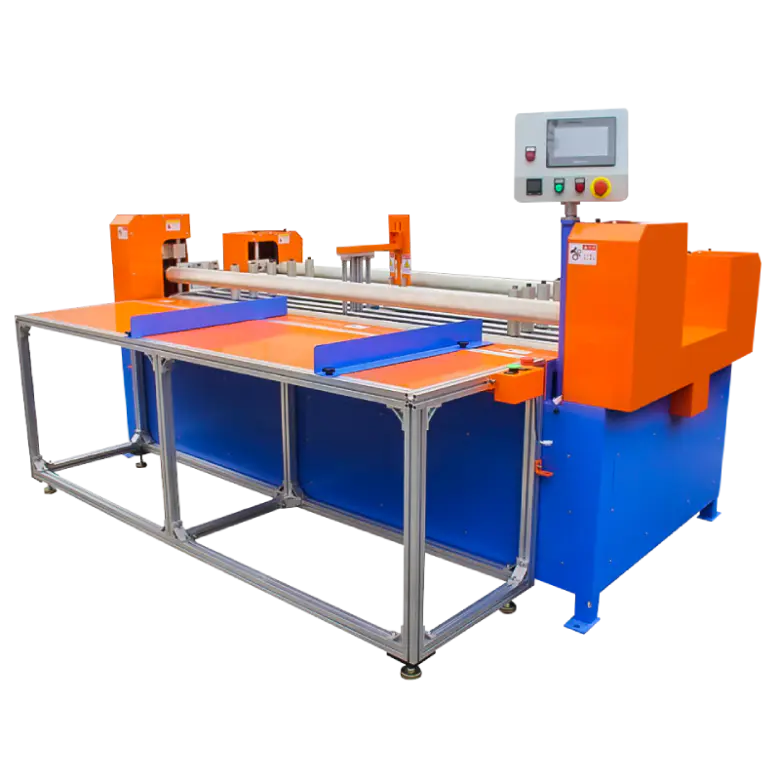

Hebei Changxing Foam Machinery Co., Ltd. is a well-known domestic company that provides foam box production equipment and other products and services. Hereby, I have introduced the company's related content and learn from each other. The production process of eps foam building module equipment has great energy-saving potential Taking injection molding machine as an example, the process of injection molding machine is generally divided into several stages, such as clamping, injection, melting, holding pressure, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow rate at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, which greatly reduces energy loss. As early as some end users were using frequency converters in eps foam building module equipment. System integrators provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect of the foam was remarkable, and the motors of eps foam building module equipment became more and more. Many eps foam building module equipment users have adopted frequency converters to transform their equipment. More similar articles: In fact, when we buy this type of equipment, we pay special attention to its quality. In fact, if we want to extend the service life of this type of equipment, as long as the daily maintenance work is done, it will naturally be guaranteed. Daily maintenance. In fact, the maintenance of the molding machine is also divided into two parts. The daily maintenance work is relatively simple, but there may be some tasks that are done every day, so we try to implement the maintenance work on the head every time the equipment is used. . Before handing over the shift every day, we must still check the equipment, and some parts may also need to use lubricant. Regular maintenance work. Regular maintenance of the molding machine is also very important. After all, some internal parts are definitely prone to wear and tear. This type of equipment must be used every day. If the internal parts are really worn out, we must also replace them. , In order to avoid more serious failures of the equipment. Through the introduction of this article, I believe that everyone has a certain understanding of 'foam molding machine maintenance is relatively simple'. If you want to know about foam box production equipment, plastic foam box production equipment, Hebei Changxing Foam Machinery Co., Ltd. and other related knowledge, Please contact us!

Custom message