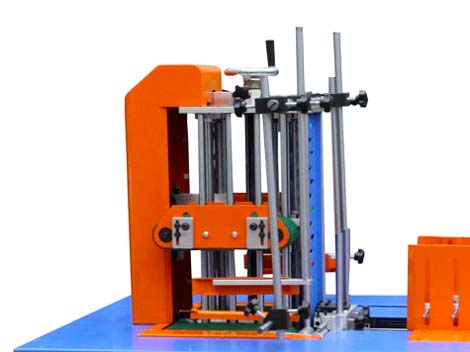

Company Advantages1. Veinas has gone through a complete design process. It has been designed in terms of mechanical structure, spindles, and drive system, control, and inspection systems, etc. Its durability ensures its prolonged working time

2. This product is widely used on account of its obvious advantage that saving people from work that is full of dullness and monotony. The product occupies only a small space

3. For the future development,

foam laminating machine is more suitable in its than other products. Its environmental friendliness helps to save much cost

4. Due to its , foam laminating machine has been widely used in many applications such as . The product owns patents on the design of appearance, practicality, and novelty

5. Comparing with common foam laminating machine , has more features. The advanced systems of the product enable its high-efficiency and simple operation

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

Z-2020 | 1200*1200*1400 | 200*200 | 2 | 2 | 0.3 |

1

Applications

Right-angle lamination for EPE foam, known as protective angle. U-type is available as well

2

Operation Principles

Adopted with electronic hot-air gun, wwo strip sheets are fixed along the transmission parts, and automatically plastified after passing through heating-wind-month

3

Performance Advantages

Faster lamination, equivalent to 5-8 labor efficiency. No yellowing, neat appearance and no malposition.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. With rich experience in R&D and production, Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd enjoys a high reputation for its foam laminating machine .

2. Fully comprehending the imported automation machinery technology will be beneficial to the growth of Veinas.

3. Putting lamination machine price list on a prominent strategic position helps Veinas's improvement. Contact us!