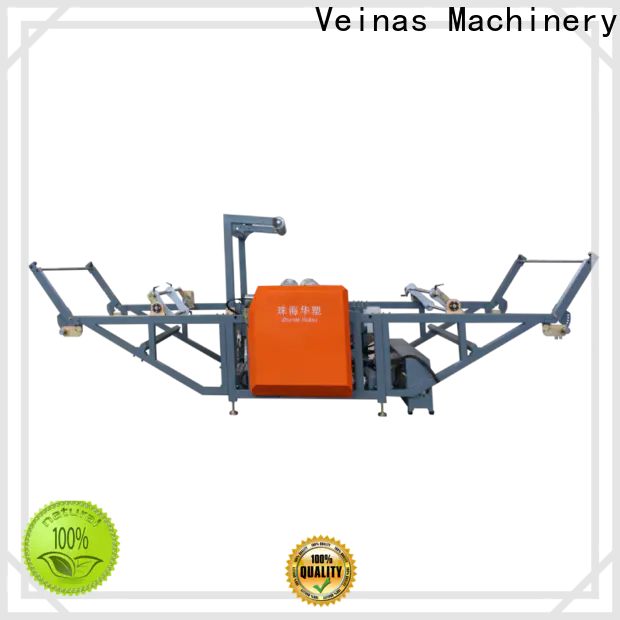

Veinas PE Foam/ Polyethylene Foam/Expanded Polyethylene Foam Laminating Machine:

Advantages:

1. Energy consumption is 15%-40% lower than the machines in the market. Saving about 3000USD/year.

2. High-configuration, high-rigid body design, the weight of the machine is 2-3 times that of the same industry, PE foam sheet after thickening is neat of the edges, when trimming and this will save EPE foam materials;

3. The composite thickness is up to 120mm, width is 1.3meters, and the design life is 10-20 years;

4. Speed: 100-104 meters/min

5. Three heater: LEISTER HEATER

6. Easy to operate, both raw and familiar hands.

Machine dimension : 1.8M*6M

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.