[Summary] Operating method of eps building module equipment Working principle of foam forming machine

by:Veinas

2021-08-15

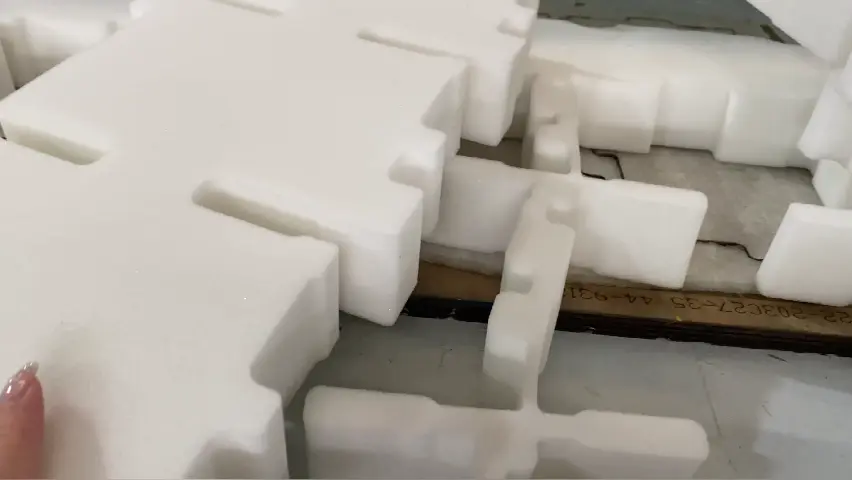

Our company is a well-known company that provides eps building module equipment, manufacturers, manufacturers and other products and services in China. I have introduced some related content before, and today I will learn the operation method of eps building module equipment. Working principle The eps building module equipment is a computer controlled machine that can cut any two-dimensional products from the extruded and expanded EPS foam. Through the use of a step motor controlled by a computer, the heating wire is cut in the X, Y and Z directions, which can make the foam material cut quickly and accurately. The principle of the eps building module equipment is to convert the CAD model of the product design to the HPGA format, and the computer-controlled micro stepping motor in the X, Y, and Z directions drives the processing tools-electric heating wire and profiling electric heating wire to cut EPS foam plastic materials , To obtain a two-dimensional EPS foam model. It has the advantages of fast processing speed, high forming accuracy, good surface quality, eps, and low manufacturing cost of the operating method of eps building module equipment. eps building module equipment is suitable for machinery manufacturing, casting, automobiles, ships, industrial design, mold manufacturing and processing, advertising, architectural decoration and decoration, foam cutting plants, foam manufacturing plants, foam molding plants, school institutions, advertising production companies, packaging plants, Exhibitions, model factories, POP crafts processing and publicity display industries. Related articles recommended: 1. The foam molding machine computer adopts imported PLC computer host chip, plus LCD screen, software fault self-diagnosis system and error correction system, which makes the operation more convenient. Its control program is designed in a fool-like manner, simple and convenient , No professional training is required to start operation. 2. The full hydraulic drive of the foam molding machine has domestic hydraulic frequency modulation technology, which solves the adaptability of the foam molding machine to various materials, improves the compactness of the materials, and shortens the molding cycle. The working principle of the foam molding machine is similar to that of the syringe. It uses the thrust of the screw to construct. The working principle of the foam molding machine injects the plasticized and molten plastic into the mold cavity, and the product is obtained after solidification and shaping. . The injection molding is a cyclic process, a cycle mainly includes: quantitative feeding-melt plasticization-pressure injection-mold filling and cooling-mold opening and taking parts. After the product is taken out, the mold is closed again to proceed to the next cycle process. The above is the whole content of 'eps building module equipment operation method foam molding machine working principleBuilding modular equipment, stay tuned! Keywords of this article: eps construction foam molding cutting control

Custom message