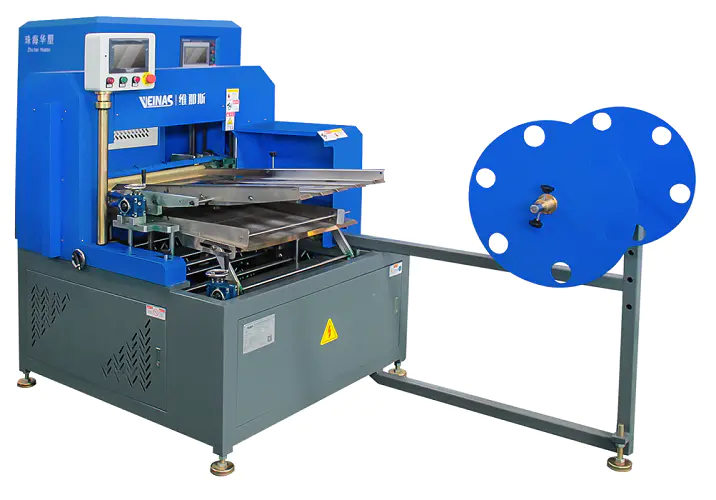

Successive Hot-Air EPE Laminator

Application:

Successive lamination of infinitely long EPE foam by theory of hot air lamination.

Performance advantage:

1. Less laminated waste(0-2mm) and save material.

2. Environmental protection, smokeless and tasteless and no need to install ventilation equipment.

3. No yellowing, drawing and scorch marks with perfect appearance after heating.

4. Maximum width of laminating is 650mm, continuously laminating and unlimited length.

5. Quickly & uninterrupted laminated, high speed and efficiency.

Working Principle:

Two strip sheets are handled into the transmission part, and meanwhile plastified to the lamination together by automatical heating when feeding.

Parameter:

Model | Machine Size(mm) | Gross Power(KW) | Effective Machining Size(mm) | Net weight(T) |

LRFJ-650 | 2500*1210*1630 | 10 | 650 | 1.2 |

Video:

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.