[Essence] Inspection and Repair Method of Foam Molding Machine Technological Revolution of Foam Machine

by:Veinas

2021-07-12

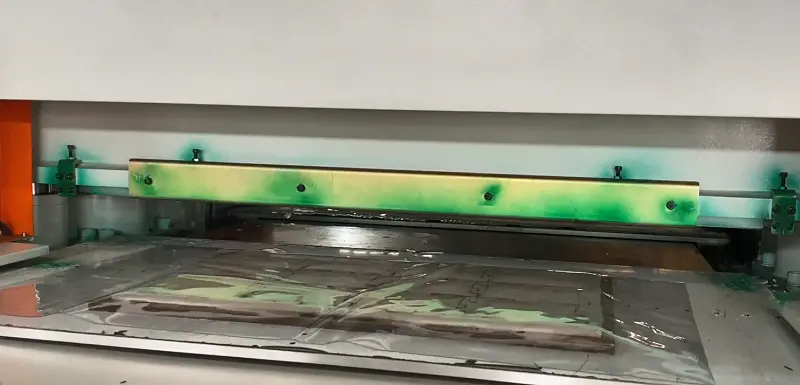

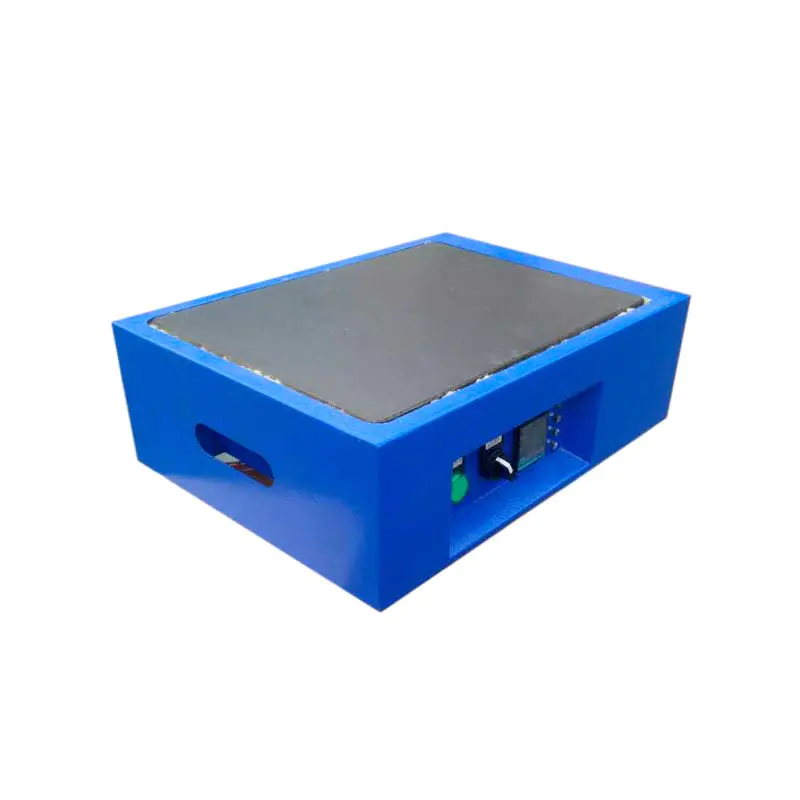

Maintenance method of foam molding machine The technological revolution of foaming machine? Today I want to introduce you to this aspect. I hope that through the introduction of this article, you can have a certain understanding and understanding of the maintenance methods and other aspects of the foam forming machine. Let’s follow the experts from Hebei Xinsu Foam Machinery. Take a look at the relevant content introduction. Foam molding machine is a kind of equipment for processing foam, sponge and other materials required by the chemical industry. At present, the laser machine is mainly used for cutting. Due to the advantages of laser beam fine cutting, it is not easy to be deformed, the incision is smooth, and there is no battered edge. Of course, it is inevitable that there will be failures during the use of the foam cutting machine and need to be overhauled. Now let's talk about the following precautions when overhauling. Only personnel who know how to use and operate are allowed to repair machinery or replace components! In order to prevent accidents or damage to the machine, the following principles must be observed during maintenance: 1. When a fault occurs, disconnect the power supply to stop the machine; 2. When the machine cannot be used normally, check the relevant manuals and use The manual determines the correct measures to be taken; the power supply must be turned off before overhauling or replacing components. 3. The parts (components) removed during the overhaul should be replaced with the same new parts (components) in situ, and the instruments used in the overhaul must be calibrated; 4. It is strictly forbidden to put flammable or metal objects in the electrical cabinet or wiring Inside the box; 5. Regularly check the cables and wires for damage to the foam, and the maintenance methods of the foam molding machine to prevent leakage or electric shock. You may want to know: Foaming machines have appeared in foreign countries for a long time, and their original models used impellers to rotate at a high speed to make foam, so they are also called 'foaming machines'. Later, with the continuous advancement of technology, the technical content of foaming machines continued to increase, new models continued to appear, and different technical systems were formed. my country began to use foaming machines as early as the 1950s, but instead of special foaming machines, mortar mixers were used. That is, the foaming agent is directly added to the mortar mixer or concrete mixer, and the foaming machine and the mortar or concrete are mixed together to generate foam. Later, around the 1970s, dedicated foaming machines, namely high-speed impeller foaming machines, began to appear. In the future, the technology has been continuously upgraded and replaced, and now it has developed into a third-generation model with high-pressure inflation as the main body, which can basically meet the needs of foam concrete. However, compared with foreign developed countries, my country's foaming machine is still relatively low in automation, and there is still a certain gap in foaming performance, which needs to be further improved. From the perspective of development trends, this gap is gradually narrowing and narrowing. The main advantage of my country's foaming machine at present is its low price. Most of the imported models are more than 100,000 yuan/unit, and the highest is 15-200,000 yuan/unit, while most domestic models are tens of thousands of yuan/unit, and the simple and small models are even several thousand yuan/unit. They have certain advantages in price. So it suits the national conditions and is welcomed by most small and medium-sized enterprises. If the foam box equipment manufacturer prepares for you the 'Technical Revolution of Foam Molding Machine Inspection and Repair MethodCome, let us make more progress. Keywords in this article: foam molding foam model use overhaul appearance

The automation equipment manufacturer approach to machine manufacturer is becoming increasingly popular; consequently, there is a surge in the demand for .

To build customers value by delivering high-quality products, services and solutions in innovative and cost effective ways. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd will realize this mission by setting the highest standards in service, reliability, safety and cost containment in our industry.

Establish a unique brand as Veinas that cuts through the clutter, and you'll get you the capital you need to get moving.

The automation equipment manufacturer approach to machine manufacturer is becoming increasingly popular; consequently, there is a surge in the demand for .

To build customers value by delivering high-quality products, services and solutions in innovative and cost effective ways. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd will realize this mission by setting the highest standards in service, reliability, safety and cost containment in our industry.

Establish a unique brand as Veinas that cuts through the clutter, and you'll get you the capital you need to get moving.

Custom message