eps foam building module equipment_technical status of foaming machine

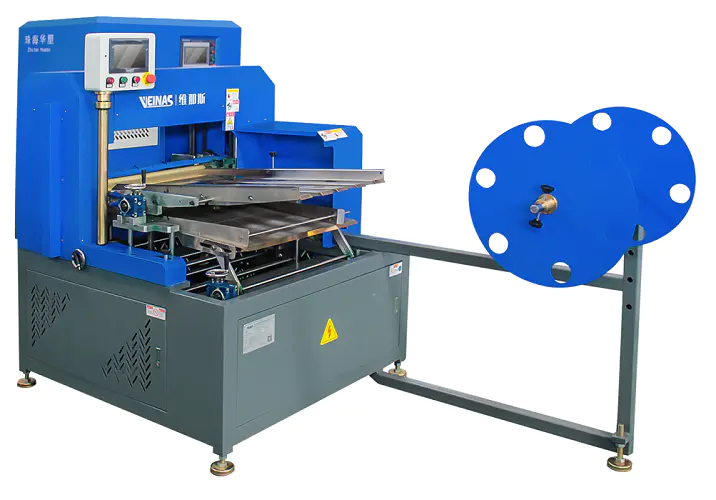

by:Veinas

2021-08-02

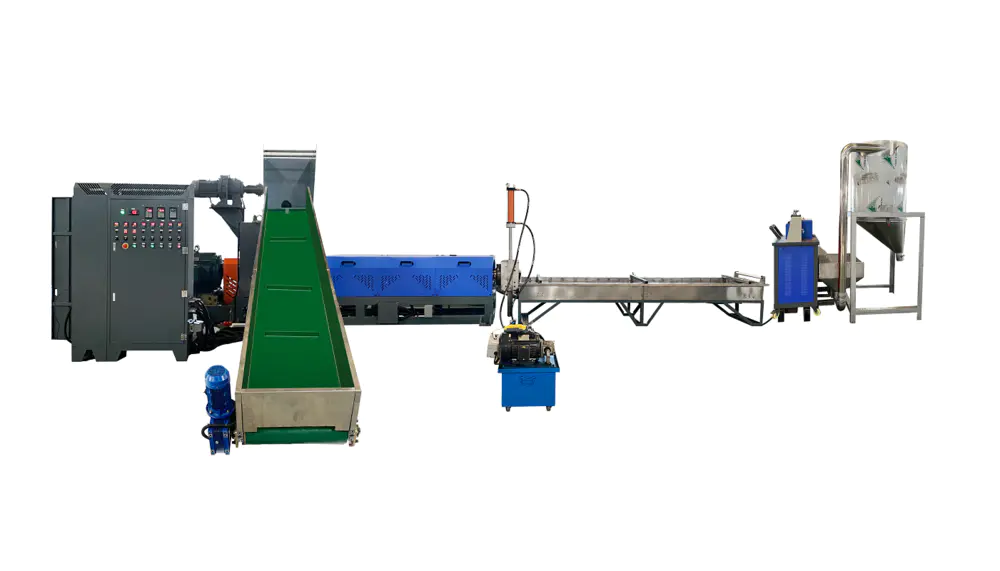

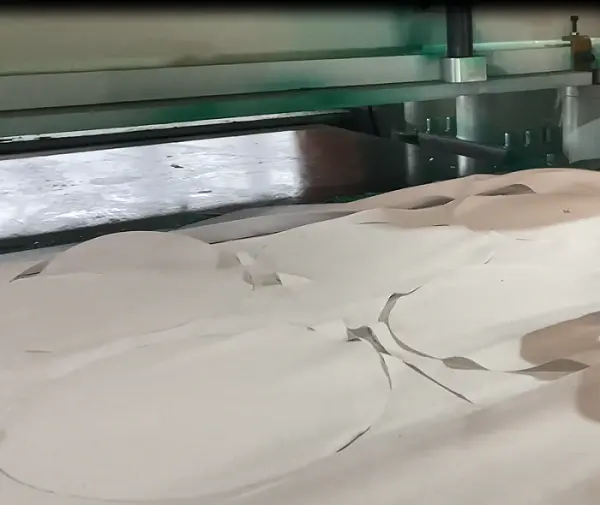

Today we will bring you eps foam building module equipment. We hope that through our introduction, you will have a deeper understanding of Huasu and other issues. The production process of eps foam building module equipment has great energy-saving potential. Take the injection molding machine as an example. , The process of injection molding machine is generally divided into several stages, such as clamping, injection, melting, holding pressure, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow rate at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, and reduce energy loss to the greatest extent. Some end users were the first to use frequency converters on eps foam building module equipment. System integrators provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect was remarkable. eps foam building module equipment is becoming more and more. Users of eps foam building module equipment used frequency converters to transform their equipment. You may be interested in the article: The foaming machine first appeared in foreign countries. Its original model used the impeller to rotate at a high speed to make foam, so it is also known as the 'foaming machine'. Later, with the continuous advancement of technology, the technical content of foaming machines continued to increase, new models continued to appear, and different technical systems were formed. my country began to use foaming machines as early as the 1950s, but instead of special foaming machines, mortar mixers were used. That is, the foaming agent is directly added to the mortar mixer or concrete mixer, and the foaming machine and the mortar or concrete are mixed together to generate foam. Later, around the 1970s, dedicated foaming machines, namely high-speed impeller foaming machines, began to appear. In the future, the technology has been continuously upgraded and replaced, and now it has developed into a third-generation model with high-pressure inflation as the main body, which can basically meet the needs of foam concrete. However, compared with foreign developed countries, my country's foaming machine is still relatively low in automation, and there is still a certain gap in foaming performance, which needs to be further improved. From the perspective of development trends, this gap is gradually narrowing and narrowing. my country's foaming machine The main advantage of the current foam foaming machine technology is that the price is relatively low. Most of the imported models are more than 100,000 yuan/unit, and the highest is 150-200,000 yuan/unit, while the domestic models are mostly tens of thousands of yuan/unit, and the simplest and smallest models are even several thousand yuan/unit. They have certain advantages in price. Therefore, it is suitable for national conditions and is welcomed by most small and medium-sized enterprises. The article 'eps foam building module equipment' and other real gold EPE foam machine provide some help for everyone. We will carefully prepare more content about Huasu in the follow-up. If you don't want to miss it, we suggest you bookmark our website!

Finding a reliable solution for the automation equipment manufacturer machine manufacturer not only supports operation of the entire system but also enhance the beauty of your workplace.

We humbly ask you to use automation equipment manufacturer and we guarantee that you would be in a great delight with using the product.

Veinas focuses on three key elements—process, people, and technology—the authors found that people of two seemingly opposite cultures are able to work together in a project-based environment to complement each other and reap mutual benefits for a win-win result.

Finding a reliable solution for the automation equipment manufacturer machine manufacturer not only supports operation of the entire system but also enhance the beauty of your workplace.

We humbly ask you to use automation equipment manufacturer and we guarantee that you would be in a great delight with using the product.

Veinas focuses on three key elements—process, people, and technology—the authors found that people of two seemingly opposite cultures are able to work together in a project-based environment to complement each other and reap mutual benefits for a win-win result.

Custom message