eps foam building module equipment motor_how foam molding machine works

by:Veinas

2021-07-30

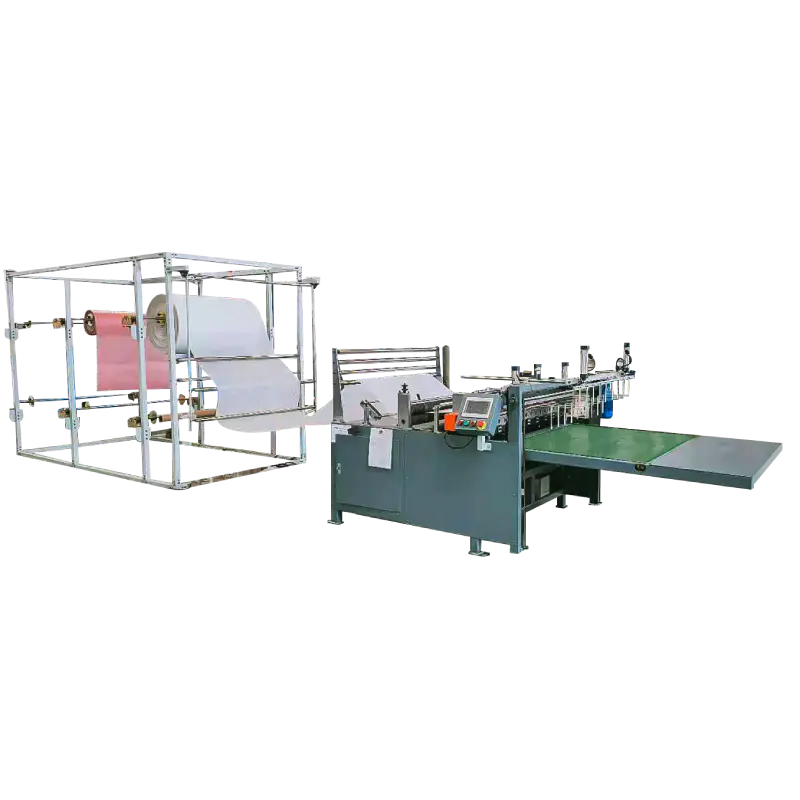

Huasu is a well-known company that provides silicon polystyrene EPE foam machine and other products and services in China. I hereby introduce the company’s related content and learn from each other. The production process of eps foam building module equipment has great energy-saving potential. Take the machine as an example, the process of an injection molding machine is generally divided into several stages, such as clamping, injection, melting, holding pressure, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow rate at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, and reduce energy loss to the greatest extent. Some end users were the first to use frequency converters on eps foam building module equipment. System integrators provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect of the foam was remarkable, and the motors of eps foam building module equipment became more and more. Many eps foam building module equipment users have adopted frequency converters to transform their equipment. More attention: The working principle of the molding machine is similar to that of the syringe used for injection. It uses the thrust of the screw (or plunger) to inject the plasticized plastic in the molten state (that is, the viscous flow state) into the closed one. In the mold cavity, the process of obtaining the product after curing and shaping. How to use the forming machine: 1. Choose a flat table and stabilize the machine. The legs of the forming machine can be pulled apart to make the machine panel easy to observe. 2. Insert the plug on the hand-held sensor head into the socket on the panel and tighten it. Pay attention to the positioning gap. 3. Insert one end of the plug of the power cord into the socket on the rear panel of the chassis, and the other end into the power supply socket. Be sure to use a single-phase three-wire power supply. 4. Turn on the 'main power switch' on the back panel of the molding machine, press the 'power switch' button on the panel, and wait for the 'ready' green indicator light to turn on, the machine can work. Well, about 'how does the foam molding machine workYou can consult by phone, and of course you can also consult our customer service online!

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is famous for creating innovative products like the automation equipment manufacturer and supporting their market leadership with savvy marketing campaigns to build an elite brand.

Applied Materials’ mission is to be the leading supplier of automation equipment manufacturer worldwide-through innovation and enhancement of customer productivity with systems and service solutions.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd affords you a suitable low price for proving our ethical considerations.

Your co-workers, investors and clients have busy schedules, and it can be hard to get everyone in the same place at the same time for automation equipment manufacturer. So, it is important to create a connection between company and clients.

comes in a vast array of styles and machine manufacturer depending on which machine manufactureris used.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is famous for creating innovative products like the automation equipment manufacturer and supporting their market leadership with savvy marketing campaigns to build an elite brand.

Applied Materials’ mission is to be the leading supplier of automation equipment manufacturer worldwide-through innovation and enhancement of customer productivity with systems and service solutions.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd affords you a suitable low price for proving our ethical considerations.

Your co-workers, investors and clients have busy schedules, and it can be hard to get everyone in the same place at the same time for automation equipment manufacturer. So, it is important to create a connection between company and clients.

comes in a vast array of styles and machine manufacturer depending on which machine manufactureris used.

Custom message