eps foam building module equipment introduction_how to use foam forming machine

by:Veinas

2021-08-16

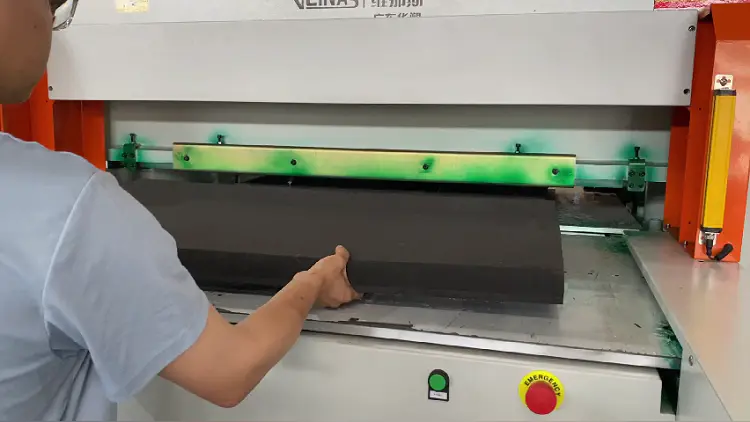

Do you know anything about Hebei Guangxing Foam Machinery Co., Ltd.? Today, the editor of Hebei Guangxing Foam Machinery Co., Ltd. will bring you a detailed introduction to the introduction of eps foam building module equipment, and let you know more about the production process of eps foam building module equipment in Hebei Guangxing Foam Machinery Co., Ltd. Very large energy-saving potential. Taking injection molding machine as an example, the process of injection molding machine is generally divided into several stages, such as clamping, injection, melting, holding pressure, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow rate at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, which greatly reduces energy loss. As early as some end users who used frequency converters in eps foam building module equipment, system integrators provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect of the foam was remarkable, and the introduction of eps foam building module equipment was increasing. Users of eps foam building module equipment adopted frequency converters to transform their equipment. You might like: The working principle of the molding machine is similar to that of the syringe used for injection. It uses the thrust of the screw (or plunger) to inject the plasticized and molten state (ie, viscous flow state) plastic into the closed one. In the mold cavity, the process of obtaining the product after curing and shaping. How to use the forming machine: 1. Choose a flat table and place the machine firmly. The feet of the forming machine can be pulled apart to make the machine panel easy to observe. 2. Insert the plug on the hand-held sensor head into the socket on the panel and tighten it. Pay attention to the positioning gap. 3. Insert one end of the plug of the power cord into the socket on the rear panel of the chassis, and the other end into the power supply socket. Be sure to use a single-phase three-wire power supply. 4. Turn on the 'main power switch' on the back panel of the molding machine, press the 'power switch' button on the panel, and wait for the 'ready' green indicator light to turn on, the machine can work. Through the introduction of this article, I believe everyone has a certain understanding of 'eps foam building module equipment introduction'. If you want to know about foam box production equipment, foam box manufacturing equipment, Hebei Guangxing Foam Machinery Co., Ltd. and other related knowledge, please follow Contact us!

Custom message