eps foam building module equipment energy-saving potential_foam cutting machine product structure

by:Veinas

2021-07-30

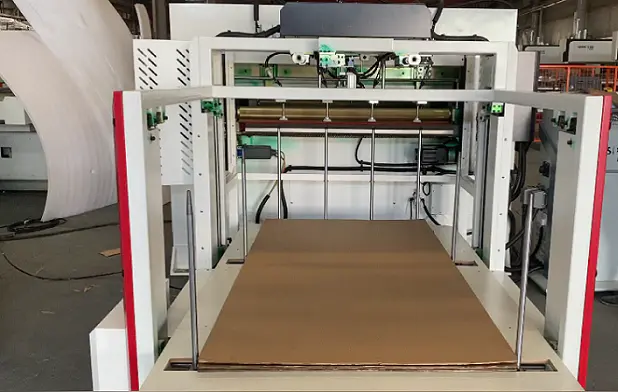

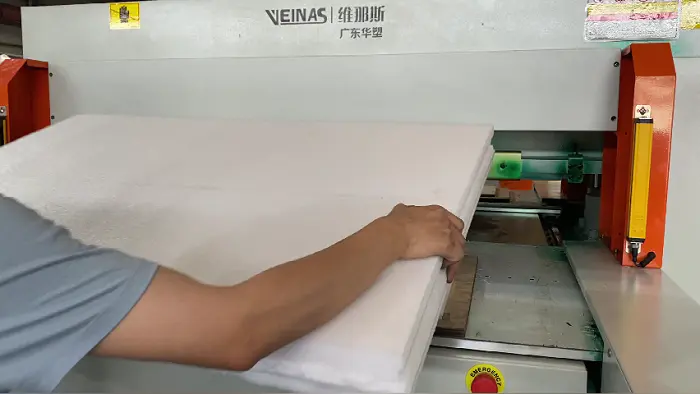

Do you know anything about Huasu? Today, Huasu’s editor will give you a detailed introduction about the energy-saving potential of eps foam building module equipment, and let you know more about Huasu. The production process of eps foam building module equipment has great energy-saving potential. As an example, the process of an injection molding machine is generally divided into several stages, such as clamping, injection, melting, holding pressure, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, and reduce energy loss to the greatest extent. Some end users were the first to use frequency converters on eps foam building module equipment. The system integrator provided them with frequency conversion energy-saving transformation schemes for eps foam building module equipment. The effect of the foam is remarkable, and the energy saving potential of eps foam building module equipment is increasing. Many eps foam building module equipment users have adopted frequency converters to transform their equipment. You may want to know: The structural characteristics of foam cutting machinery are as follows: 1. Equipped with a movable cutting and adjusting device. In order to ensure the size and accuracy of the cutting material, the machine is equipped with a digital display ruler. 2. The movable worktable adopts the suction method of negative pressure, and the cut foam can be fixed and not shifted randomly. 3. When the operation is stopped, it is equipped with manual and automatic devices. 4. The red brake button of the foam cutting machine is used for manual braking. When the start button is pressed, this button becomes invalid. When the brake electromagnets are attracted to each other, press the start button again, and the brake electromagnet will be released immediately. If the 'Energy Saving Potential of EPS Foam Building Module Equipment' prepared by Huasu is helpful to everyone, I hope to collect it. If there are any shortcomings, I hope you can point it out to us and let us have more improvement.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd thinks that customer satisfaction is one of the most important determinants of brand loyalty. High-quality service can be the difference between a one-time buyer and a lifelong repeat customer.

Veinas provides supreme quality and ultimate using experience.To know in detail about the prices please visit Veinas Machinery.

Along the way, Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd will face a wide range of challenges. The most successful will show our resolve by working through the challenges and finding ways to improve and grow.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd thinks that customer satisfaction is one of the most important determinants of brand loyalty. High-quality service can be the difference between a one-time buyer and a lifelong repeat customer.

Veinas provides supreme quality and ultimate using experience.To know in detail about the prices please visit Veinas Machinery.

Along the way, Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd will face a wide range of challenges. The most successful will show our resolve by working through the challenges and finding ways to improve and grow.

Custom message