What are the advantages of advanced foam machinery

by:Veinas

2021-07-06

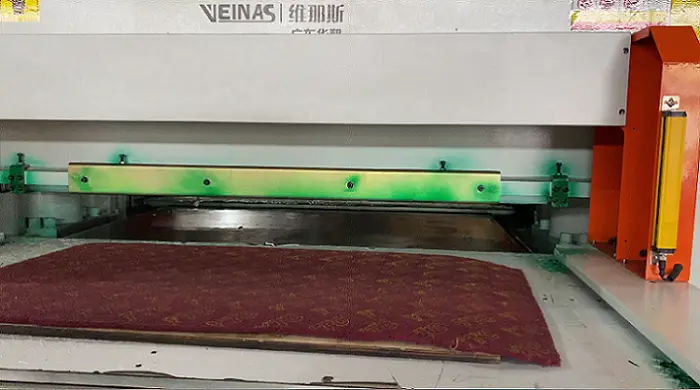

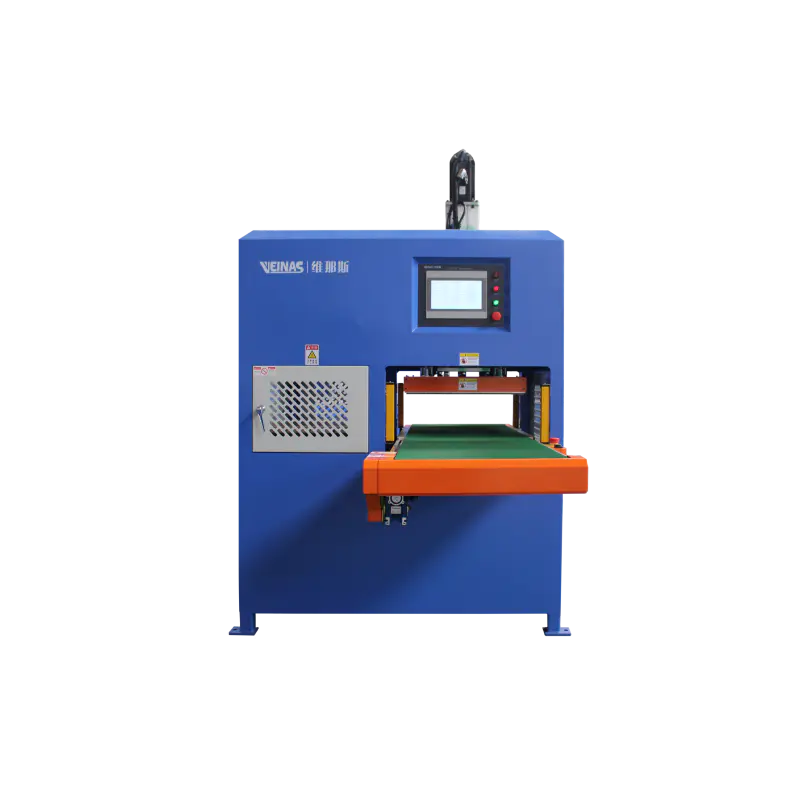

• The foaming machine adopts PLC programmable controller, automatic feeding, electronic weighing, temperature control, material level control, etc., and can customize the density control system according to customer needs to realize automatic and intelligent production; The plastic mechanical foaming machine adopts screw feeding device and electronic weighing device; • The foam plastic mechanical foaming machine adopts a fully enclosed foaming barrel and pressure control technology, which can continuously sample, make the foaming pressure more constant and greatly increase Improve the thermal efficiency and save steam; • The foaming machine adopts famous-brand electrical components, pneumatic components, valves, etc. The quality is reliable. They are all domestic and foreign brand-name products, ensuring precise control of temperature and pressure, controlling the density of foaming materials, and making foaming. The density of the material particles is uniform; • The equipment can be equipped with a high-temperature vulcanization drying bed to realize drying, automatic screening, crushing, and conveying the foamed material particles to the curing silo. • The foam plastic mechanical sheet forming machine adopts PLC computer touch display screen control, so that the machine opens, closes, feeds, heats, heats up, vacuum cools, and ejects the finished product, realizing fully automated cycle operations. • The surface of the mold cavity of the foam-plastic mechanical sheet forming machine adopts a special aluminum alloy main board, which has high heat conduction efficiency, good tensile strength and long life. • The foam plastic mechanical sheet forming machine adopts a high-efficiency vacuum pump cooling device, which has strong penetration, good adhesion, less steam, fast forming speed, and low water content, which can ensure the internal and external consistency of the thickened foam board and production efficiency multiply. • The foam mold core adopts a synchronous speed changer, with a large adjustment range, and the lifting size can be adjusted arbitrarily, realizing multiple uses in one machine. • The foam mechanical cutting machine is equipped with horizontal, vertical and block cutting devices, which can realize horizontal, vertical and block cutting in three directions. • The foam plastic mechanical cutting machine adopts frequency conversion speed regulation, stable movement, wide speed regulation range, and realizes stepless speed regulation of 0-4m/min, which is suitable for the requirements of slow cutting and fast retraction. . The foam mechanical cutting machine is equipped with an integral block cutting system, which improves the production efficiency and the block size accuracy. Particularly suitable for cutting wall panels. The advanced high-end foam plastic machinery and equipment have a long life span, and the electrical appliances adopt famous-brand electrical components, pneumatic components, valves, and other reliable quality. The production process adopts German production technology, which saves 20% of steam. The product quality both internally and externally meets the international first-class foam product standards. The production speed is fast, and the fully automated operation saves labor costs. Quality is the foundation of the enterprise (please go around if you are looking for low-priced equipment, what we do is quality) Hebei Xinji Foam Machinery has continued to innovate on the road of development since the establishment of the factory, and is on the basis of fine management. The company has gradually carried out brand building work in the past. The company has always adhered to the value innovation concept of high efficiency, high quality, and low energy consumption. It has set new standards in scientific and technological research and development, refined product manufacturing, thoughtful and fast service system, and strictly followed Standard implementation. The company produces more than 60 different specifications of foam machinery and molds, which are exported to more than 80 countries and regions. While expanding the sales network, it maintains close communication with customers. Our factory provides you with the best quality, the most suitable price, and the most comprehensive service foam plastic machinery. We will provide you with the most professional and reliable equipment solutions and life-long service! What are the advantages of advanced high-end foam machinery?

are important in ensuring machine manufacturer, and the machine is utilised by everyone from machine manufacturer to machine manufacturer.

Reach us at Veinas Machinery. We'll always try to give you the BEST deal on . If we can't, we'll at least give you some hel pful advice. Please use our experience!

We persevere in keeping the customers pleasant and supporting them with automation equipment manufacturer at a reasonable price.

Individuals with varied technical skills use automation equipment manufacturer in a wide range of applications.

It's the consistent experience that builds trust and loyalty. Creating a personality and platform that is scalable will allow you to evolve automation equipment manufacturer with your consumers.

are important in ensuring machine manufacturer, and the machine is utilised by everyone from machine manufacturer to machine manufacturer.

Reach us at Veinas Machinery. We'll always try to give you the BEST deal on . If we can't, we'll at least give you some hel pful advice. Please use our experience!

We persevere in keeping the customers pleasant and supporting them with automation equipment manufacturer at a reasonable price.

Individuals with varied technical skills use automation equipment manufacturer in a wide range of applications.

It's the consistent experience that builds trust and loyalty. Creating a personality and platform that is scalable will allow you to evolve automation equipment manufacturer with your consumers.

Custom message