What are applications of foam lamination machine produced by HuaSu Automation Machinery Equipment?

2021-12-01

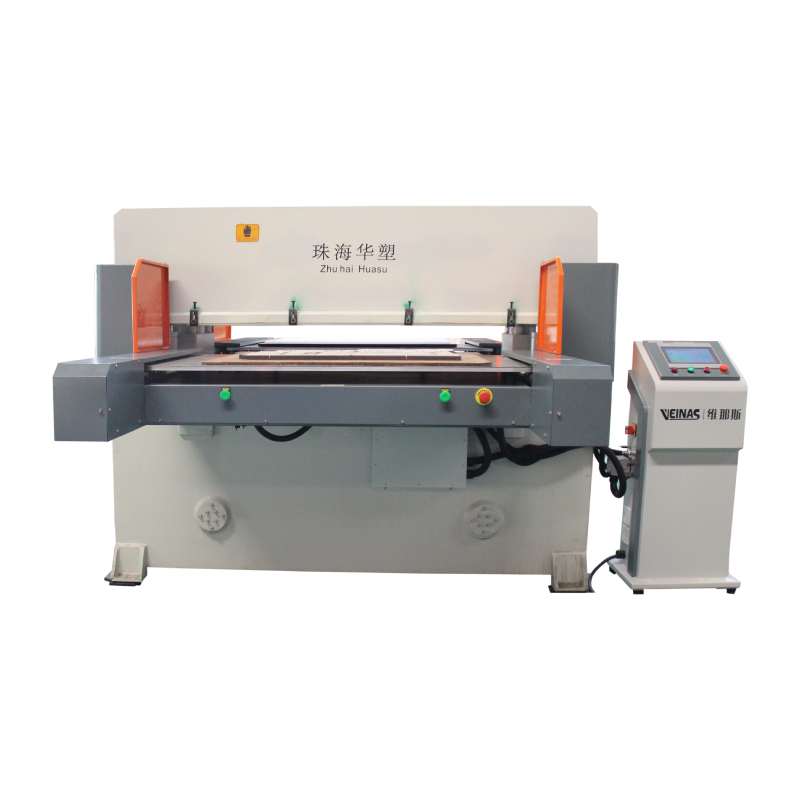

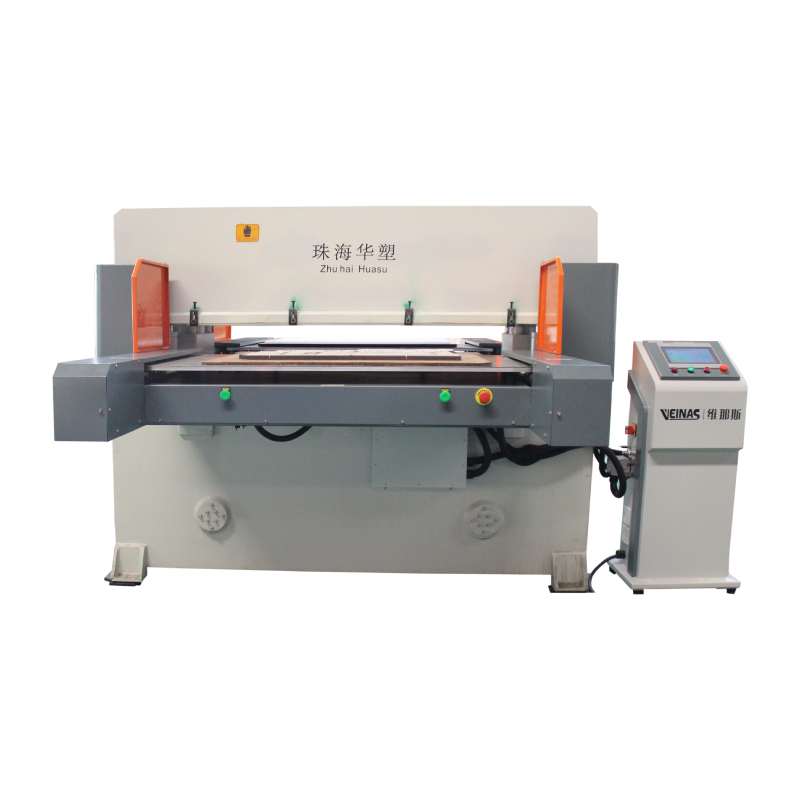

Foam lamination machine is a product which has many fine qualities and has a large assortment of applications. Those developed by Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has received lots of attention in the field because it reduces customer pain that no other company is solving. The product has important product features likely to lead to wide customer adoption. The material we choose, as well as the manufacturing technology we gain all contribute to its practiceability in daily life. Please contact us to learn more about its applications in various scenarios.

HuaSu Automation Machinery Equipmentry has always been synonymous with high-end automated machine products in China. HuaSu Automation Machinery Equipment focuses on providing a variety of punch equipment for customers. Offered Veinas foam board cutting machine is manufactured in complete compliance with the industry standards. It is well-known for energy-saving with advanced technology. The product is strong because designing and manufacturing are executed using highly automated machines and computer-aided designing technology, which effectively result in products with great structural strength. The product has a characteristic of noiselessness.

Our firm bears societal obligation. We have methods of reducing carbon footprint which ranges from designing next-generation products to working proactively to achieve zero waste to landfills by investing in advanced gear into recycling the sterile waste out of manufacturing.

HuaSu Automation Machinery Equipmentry has always been synonymous with high-end automated machine products in China. HuaSu Automation Machinery Equipment focuses on providing a variety of punch equipment for customers. Offered Veinas foam board cutting machine is manufactured in complete compliance with the industry standards. It is well-known for energy-saving with advanced technology. The product is strong because designing and manufacturing are executed using highly automated machines and computer-aided designing technology, which effectively result in products with great structural strength. The product has a characteristic of noiselessness.

Our firm bears societal obligation. We have methods of reducing carbon footprint which ranges from designing next-generation products to working proactively to achieve zero waste to landfills by investing in advanced gear into recycling the sterile waste out of manufacturing.

Custom message