Company Advantages1. Veinas has a professional design. It is created by professionals who understand the fundamentals of designing the most commonly used parts, elements, and units of various machines. It has a variety of sizes and dimension for options

2. This product has won the good reputation and trust of domestic and foreign customers. It is much convenient and precise for users with touch screen function

3. With its components or parts soldered together, which helps improve its inner strength and stability, this product features long-lasting durability. The product owns patents on the design of appearance, practicality, and novelty

4. The product is of high precision. It is manufactured by a variety of specialized CNC machines such as a cutting machine,

punching machine, polishing machine, and grinding machine. The advanced systems of the product enable its high-efficiency and simple operation

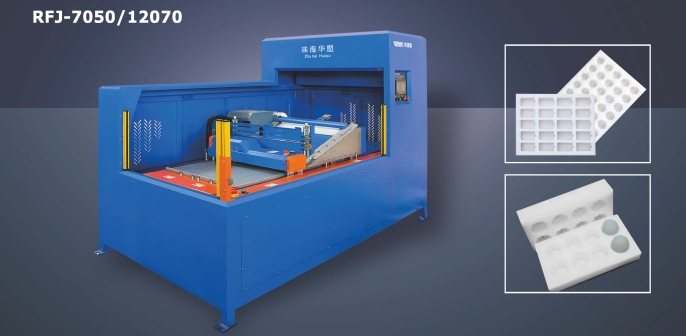

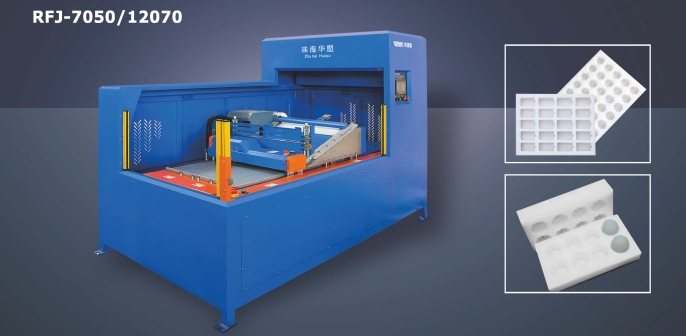

Automatic Hot-Air EPE Laminator

Application:

Both upper and bottom EPE foam could be laminated together by theory of hot-air lamination, up to 5 layers of product laminating can be carried out.

Performance advantage:

1. Simple operation with one person.

2. High efficiency, some products up to 7 seconds/piece.

3. Less waste(can be less than 2mm) and save material.

4. Environmental protection, smokeless and tasteless and no need to install ventilation equipment.

5. No yellowing, drawing and scorch marks with perfect appearance after heating.

Working Principle:

Blow hi-temp hot air to surface of EPE upper and lower layers to be bonded, push upper EPE layer downward by rollers to laminate two layers of EPE together.

Parameter:

Model | Machine Size(mm) | Gross Power(KW) | Effective Machining Size(mm) | Net weight(T) |

RFJ-7050 | 2300*2080*1350 | 13 | 700*500*230 | 1.4 |

RFJ-12070 | 2950*1600*2080 | 16 | 1200*700*230 | 1.9 |

Video:

Company Features1. Veinas is more and more mature in the development and operation of letter laminating pouches .

2. We have a project management team. Relying on years of experience in the industry, they are able to provide timely and accurate guidance for our customers and manage well our projects.

3. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's mission is to provide the best service to our customers through our global partners. Ask!