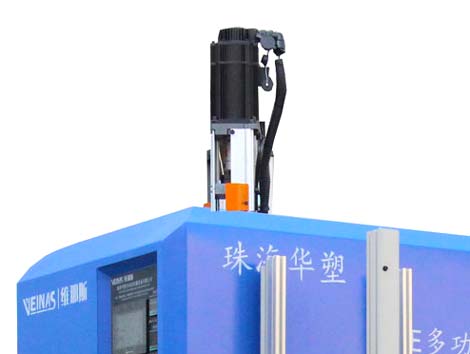

Company Advantages1. Veinas foam machine follows many standard operating procedures. It features strong toughness and stability

2. This product can effectively reduce monotony. It is good at creating a healthy environment, reducing boredom and monotony for people. The product occupies only a small space

3. This product has highly reliable mechanical properties. Its mechanical parts are processed in hot or cold ambient temperatures and have good safety performance. Its high quality and accuracy guarantee its safety usage for operators

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

QJC-7050 | 3230*2150*2350 | 500*700 | 17 | 8 | 3.5 |

1

Applications

Mainly used for the lamination of upper and bottom EPE sheets together with auto-feeding and auto-discharging accessories.

2

Operation Principles

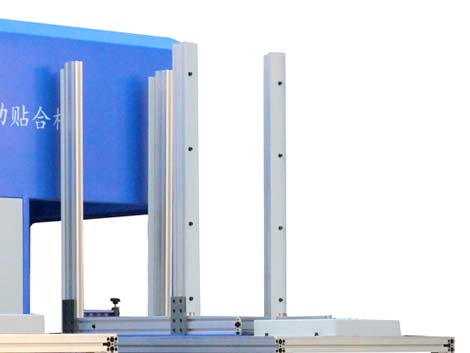

After feeding automatically, by using high temperature heating board, this machine melts around 3mm thickness of the upper EPE sheet, and quickly combines it with the lower one. Then discharge the finished product from the conveyor belt automatically.

3

Performance Advantages

1. By using multi-axial servo, advanced imported components and controller, which runs smoothly and steadily.

2. Easy maintenance.

3. Simple operation by advanced system.

4. Safer and more reliable.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is known as a reliable manufacturer and supplier of bonding machine. We have made extraordinary achievements over the years. The factory has implemented a scientific production control system for years. Under this system, we require all products, including parts and materials, to undergo rigorous quality testing under specific testing equipment.

2. The factory has established a strict quality management system. This system requires quality control to be carried out in such aspects as materials' quality, workmanship, and utilization of resources.

3. The workshop runs in accordance with the requirements of the international ISO 9001 quality management system. This system has stipulated complete requirements for all-round product inspection and testing. We advance sustainable manufacturing practices for environmental, manufacturing, and economic benefit. We yield net energy and production waste reductions.