Company Advantages1. Veinas is manufactured by dedicated and experienced technicians having years of experience. It works well even in very bad conditions

2. plastic lamination machine products from Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd pursue high quality and low prices. The product produces no smoke and smell

3. The product will not accumulate too much heat. Its substrate used has improved heat dissipation, which greatly lowers the operating temperature. It has a variety of sizes and dimension for options

4. This product has good thermal stability. It is not easily prone to color fading or performance changes in high-temperature environments. The imported advanced components and controller ensure its stable performance

5. Fatigue resistance is one of the most important mechanical characteristics of this product because it is generally used under cyclic loading conditions. The product occupies only a small space

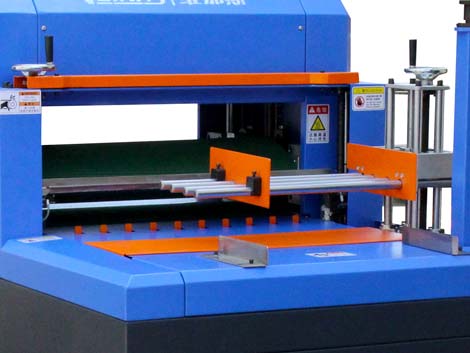

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

RFJ-7050 | 2625*1900*1200 | 700*500 | 13 | 8 | 1.4 |

1

Applications

Successive lamination of infinitely long EPE foam by theory of hot air lamination.

2

Performance Advantages

1, Two strip sheets are handled into the transmission part, and meanwhile plastified to the lamination together by automatical heating when feeding.

2, The loss is low when two EPE foam are laminated by hot air.

3, The successive laminated width is 800mm by hot air without the length constraint

4, The appearance of laminated EPE edge is good without any yellowing and scar.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is a Chinese main exporter for plastic lamination machine .

2. For years, we have received many honorable prizes in the industry. For instance, we have been awarded as "China Famous Exporter", which means that we are strong enough to serve overseas customers.

3. Dreaming to be a competitive bonding machine manufacturer has been kept in Veinas's mind. Inquiry!