Company Advantages1. Veinas

roll to roll lamination machine has been tested for quality. All its main components, including the gears, pistons, engines and other moving parts, are tested to meet our established standards.

2. automatic lamination machine with roll to roll lamination machine fully convey the concept of roll to roll laminator .

3. automatic lamination machine is designed to provide roll to roll lamination machine features over a long service life.

4. The product requires a low number of workers to execute production tasks, which will help reduce labor costs and help manufacturers achieve a competitive advantage.

5. The product is safe and secure for people during operation. People can rest assured that potential safety hazards are not possible to occur.

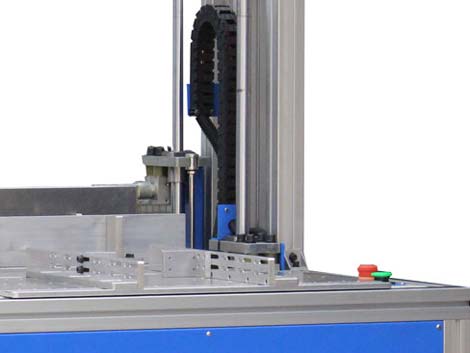

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HS-HZ2 | 1090*1800*1600 | 700*250 | 17 | 5-6 | 0.6 |

HS-HZ4 | 2180*1800*1600 | 700*250 | 22 | 7-8 | 0.9 |

1

Applications

It is optional for two-work-station or four-work-station. Dimension of EPE foam is adjustable for box-making processing upon the requirements.

2

Operation Principles

Putting the EPE foams in the fixtures in the same direction. One side moves to the vertical ironing plate for heating by the fixture after the upward ironing plate is heated, and instantly laminate together with another one for the box-making completion.

3

Performance Advantages

1、Control by servo motor, easy to operate;

2、High precision, suitable for produce all kind of high-class EPE foam box;

3、Easy to operate, heating plate away from operator which will be safety;

4、Working efficiency is much higher than made by manual.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. With many years of experience in manufacturing roll to roll lamination machine , Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has been a qualified producer in the industry.

2. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has skilled and experienced technicians to produce automatic lamination machine .

3. Corporate sustainability is integrated into every facet of our work. From volunteerism and financial donations to reducing the environmental impact and providing sustainability services, we ensure that all our employees have access to corporate sustainability. Except for production, we care about the environment. We have been proceeding with efforts toward environmental protection in all aspects of our business activities. We are committed to maintaining the highest ethical standards in our business. We have implemented an Integrity Management Plan that sets out the administrative structure and measures for integrity management.