Company Advantages1. During the design stage of Veinas foam lamination process , different factors have been considered, including structural configuration, structure connectivity and interface, structural stiffness and associated mechanical performance. The product features a large information storage capacity

2. This kind of product can easily accomplish the arduous work that people can't do. This will undoubtedly increase labor productivity and ease the pressure on workers. With auto operation function, it helps save labor cost and reduce the misoperating rate

3. Every piece of the product is strictly checked according to the international quality system. Its high quality and accuracy guarantee its safety usage for operators

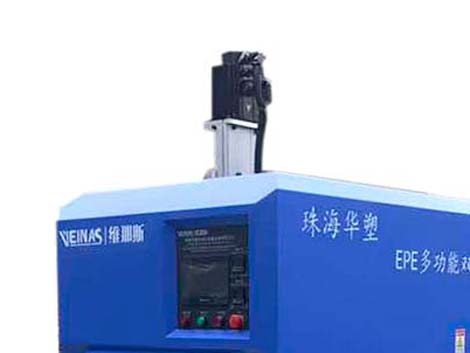

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly. Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension (mm) | Machining size(mm) | Gross Power(KW) | Power Consumption (KWH) | Net weight(T) |

VK-7050 | 2850*1000*2580 | 500*700 | 17 | 7-8 | 1.3 |

VK-9060 | 3470*1190*2650 | 600*900 | 25 | 11-12 | 1.4 |

VK-12065 | 3600*1460*2700 | 650*1200 | 29 | 13-14 | 1.7 |

VK-12080 | 4300*1460*2700 | 800*1200 | 34 | 15-16 | 1.8 |

VK-120110 | 5630*1540*2700 | 1100*1200 | 40 | 18-20 | 2.3 |

1

Applications

Mainly used for EPE lamination between the upper and lower layers, instead of traditional hot-air gun and hot-melt adhesive.

2

Operation Principles

The upper EPE layer is moved onto the ironing station for heating by the principal axis and burnt around 3mm for the instant lamination together, Instead of the tedious manual operation.

3

Performance Advantages

1.Steadily running with multi-axis servo control, imported electronic components and controller;

2.Easy maintenance;

3.Advanced equipment system and simple operation;

4.Safer and more stable.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Veinas is an influential industrial laminating

machine manufacturers supplier. It is recognized that industrial laminator is highly recommended by customers for its high quality.

2. Strictly following the quality management system more guarantees the distinguished performance of Veinas machine .

3. With a view to guaranteeing quality of foam machine , Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd introduced sophisticated facilities. We have explored many ways to upgrade our production procedure. They are mainly upgrading or replacing facilities to achieve greener production and investing in clean and renewable resources.