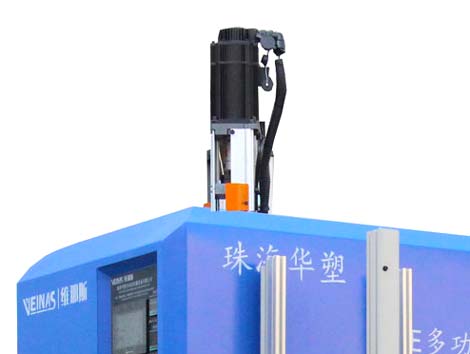

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

QJC-7050 | 3230*2150*2350 | 500*700 | 17 | 8 | 3.5 |

Crepe On A Stick Machine

Specification

1.Model No.:TEC-1

2.Material: Stainless steel

3.Power:6kw

4.Size: 390x415x195mm

5.Packing Size: 450x485x230 mm

6.Temperature range: 50-300 degree

7.N.W.: 19kg

8.G.W.: 20kg

| Name | Crepe On A Stick Machine |

Model

| TEC-1 |

Energy

| Electric |

Voltage

| 220-240V |

Power

| 50HZ/3KW |

Dimension

| 390x415x195mm |

Heating element

| High efficency heating tube |

Mainly material

| stainless stell body |

Net Weight(KG)

| 19KG |

Function

| be used for drop scones, potato cakes and pancakes |

Application | Suitable for Restaurant, Hotel, Cake House, Bakery, fast food resturant, snack bar, western food resturant |

Advantage

| easy to control the temperature and clean |

Packing

| Carton+chipboard ,one set into one carton |

Payment Terms

| T/T |

Shipping Terms

| FOB, CFR |

MOQ

| 10 Sets |

Delivery Time | 15-35 Days, according to your order quantity |

Features And Advantage

1. High efficacy heating system can heat fast and evenly. The thick cast iron plate can work continuously to cook food

2. Stainless steel body with a diameter 400mm of round heater, a drawer style warmer in the bottom of the body.

3. Console style design and all stainless steel structure with down storage cabinet. It is very solid and durable

4. Two high efficacy heaters can be controlled alone and gas valve with safety flameout device can keep safety

5. The cooking plate is coated with teflon.

6. Welded and polished corners for hygiene and easy cleaning.

7. Easy to be operated and cleaned.

8. Our crepe machine has pass CE certification

9. We have a professional R&D team to keep on R&D new products, and can do OEM for you

10. We are a factory, we manufacture products by ourselves.

11. We have complete test equipments and strict QA team to ensure products quality. And strive to make everyone who used our products be our advertiser

12. We have a professional and enthusiastic sales team to answer and solve all questions and problems you meet.

Method of operation

1. Clean the cast iron and check the gas valve is shut off

2.Get through gas supply and check everything is all right then operate the machine.

3. Press the knob and turn it and press the ignition switch at the same time. User can see electric spark through the watch hole and do it again till the pilot is fired

4.Press the knob for 15s after the pilot is fired and loosen hand and turn the knob counter-clockwise to fire the burner.

5. Turn the knob counter-clockwise to get the max fire and go on to the top then the fire is min. Turn the knob clockwise to the end then the gas valve is shut off

Certification

Package

| Product name | griddle crepe machine |

| Model No | SW663 |

| Gift Box Size | 58.3*78*24.5 |

| Cotton box size | 59.3*33.5*26 |

| PCS/20ft | 2160 |

| PCS/40ft | 4480 |

| PCS/40hgft | 5260 |

| Packing way | gift box+ carton box |

| Means of delivery | Land, Ocean, Air |

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.