Company Advantages1. Using the latest technology throughout the whole production process, Veinas epe foam sheet production line is fine in workmanship. The product produces no smoke and smell

2. With the help of this product, product costs have been greatly lowered. It significantly helps reduce the amount of money used to pay workers. The product has a characteristic of noiselessness

3. The product has the desired capability. The technology adopted goes beyond the limitations of manual capabilities. It is able to finish more complex and intricate operations. It features a characteristic of user-friendly and easy to install

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

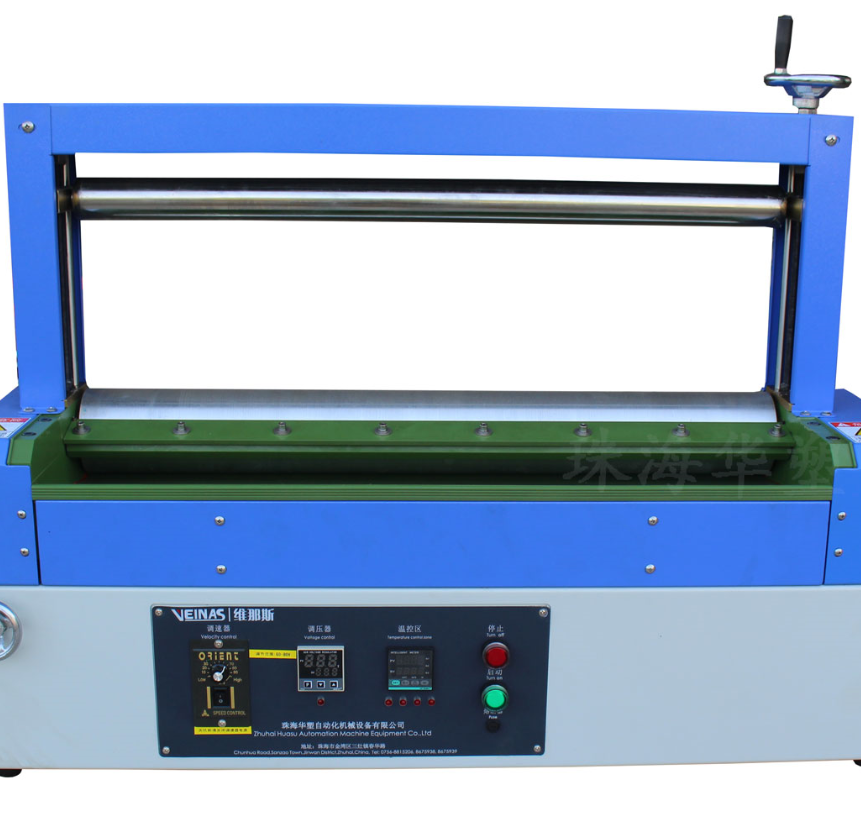

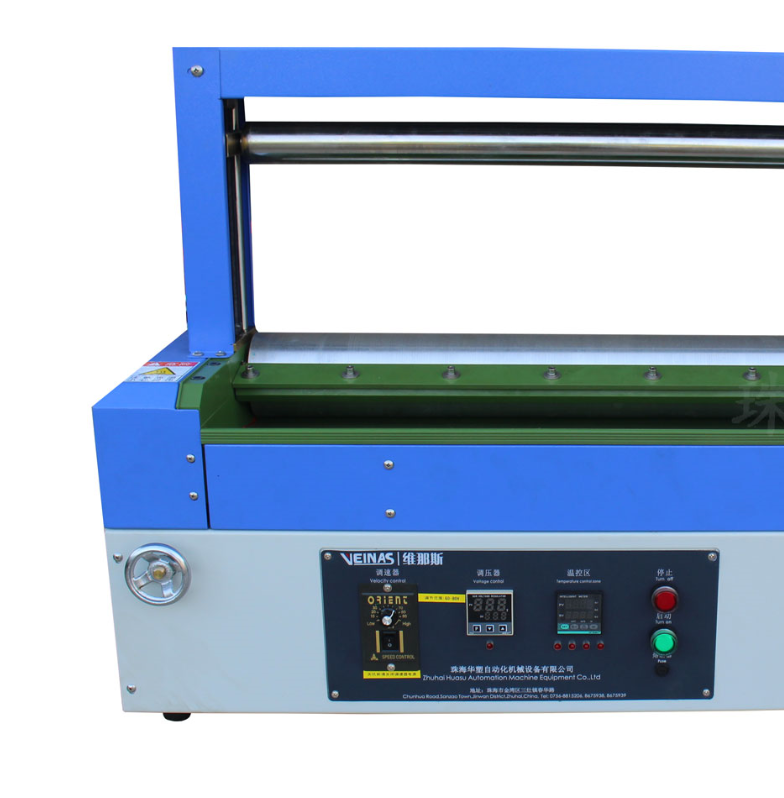

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

RRJ-01 | 630*330*300 | 400 | 3.6 | 90 | 0.2 |

RRJ-02 | 830*330*300 | 600 | 4.5 | 120 | 0.3 |

1

Applications

Used for uniform bonding and shaping of EPE foam, sponge, EVA, EPP, paperboard.

2

Operation Principles

Heated by the intelligent automation control, the plastic particles melt rapidly and are coated on the object evenly according to a set amount of the adhesive.

3

Performance Advantages

1.Novel design, handsome appearance, compact and reasonable structure, the unique nano-coating on the glue groove can protect the plastic particles from turning yellow or non-adhesive.

2.Intelligent automation control, easy operation.

3.Fast melting speed, adjustable coating glue amount, adjustable running speed.

4.Fully enclosed structure of the glue groove ensures that glue will not leak.

5.Suitable for bonding thin and large-size materials.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. For many years, Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has been providing high-quality and cost-competitive products to the global market, such as . Our manufacturing plant has equipped with well-controlled production lines. These lines are all controlled by the QC team. From product production, assembly, to testing, all these lines conform with strict quality management systems.

2. The workshop runs in accordance with the requirements of the international ISO 9001 quality management system. This system has stipulated complete requirements for all-round product inspection and testing.

3. We have a professional management team. Based on their expertise and experience, they are able to provide innovative solutions in terms of manufacturing process and order management. We are committed to run business in a healthy and sustainable way. We conduct production and business activities in an environmentally and socially responsible manner. We have the confidence to reduce our carbon footprint and pollution on the environment.