Company Advantages1. The manufacture of Veinas foam cutting tools is professional. The process mainly includes metal material purchase, rack manufacturing, component processing assembly, and debugging.

2. Propertiesfoam cutting tools can be seen in this slitting cutter .

3. Among the main requirements of slitting cutter , foam cutting tools determines its future commercial feasibility.

4. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has continued to improve slitting cutter quality management system.

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

SRQJ-8060 | 1140*930*1200 | 12 | 800*600*200(density under 80Kg) | 6 | 0.5 |

SRQJ-12060 | 1540*930*1200 | 15 | 1200*600*200(density under 80Kg) | 8 | 0.55 |

1

Applications

EPE sheet is cut into the square pieces as per the requirements.

2

Operation Principles

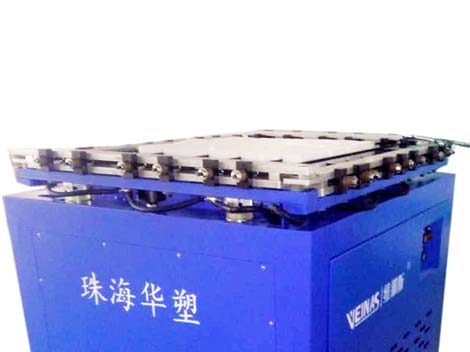

The cutters are heated up to the certain temperature by electric soldering machine, which are driven upward and downward for the fast movement by air cylinder as to complete the EPE cutting. The position of cutters is adjustable.

3

Performance Advantages

The heat-up of cutters is good for cutting effect. The position adjustment of cutters is convenient for the demand of different dimensional EPE products.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. After years of solid development in China, Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has become one of the major market players when it comes to the R&D and manufacture of foam cutting tools .

2. The company possesses excellent technical and R&D team who develop innovative products with rigorous attitude and strict standards and proactively push the industry moving forward.

3. We aim to become a reliable partner, creating long-term joint value. We support and accelerate our customers’ growth thanks to innovative, qualitative and performing products and solutions. We are aware of the importance of environmental sustainability. We set the ecological goal of preventing contamination of our local environment and legally built our own water treatment facilities.