Company Advantages1. Body frame optimum design and advanced technology application can be seen from our cutting eva

foam cutting machine . The product has access to a wide range of custom production use

2. Enough storage capacity in Veinas can also guarantee the special order from customers. The product features a large information storage capacity

3. Strict quality standards have been set in the inspection process, ensuring the high quality of the product. The advanced systems of the product enable its high-efficiency and simple operation

4. The product sets indusry standards for quality and safety. With the flexible operation, the production speed is allowed to adjust freely

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

SRQJ-8060 | 1140*930*1200 | 12 | 800*600*200(density under 80Kg) | 6 | 0.5 |

SRQJ-12060 | 1540*930*1200 | 15 | 1200*600*200(density under 80Kg) | 8 | 0.55 |

1

Applications

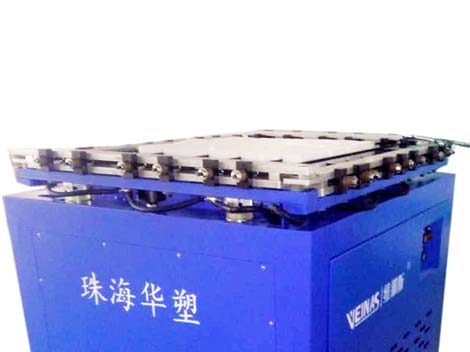

EPE sheet is cut into the square pieces as per the requirements.

2

Operation Principles

The cutters are heated up to the certain temperature by electric soldering machine, which are driven upward and downward for the fast movement by air cylinder as to complete the EPE cutting. The position of cutters is adjustable.

3

Performance Advantages

The heat-up of cutters is good for cutting effect. The position adjustment of cutters is convenient for the demand of different dimensional EPE products.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is a leader in cutting eva foam cutting machine field.

2. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has won the big marketplace of mattress machine with its strong technical base.

3. We will continue to focus on driving down our emissions from energy as well as look at improving the way we collect data on our resources use, for example, waste and water. Inquire online!