Company Advantages1. roll to roll lamination machine wins good reputation for its selected materials and well-made features. It features strong toughness and stability

2. The product, with an increasing reputation in the market, has a great developmental prospect. It is well-known for energy-saving with advanced technology

3. The product has been quality tested before delivery to ensure that it is flawless and free from any defect. It features a characteristic of user-friendly and easy to install

4. This product is cost-effective and has comprehensive quality and functions. It has the advantage of strong database backup and automatch

5. Our strict quality management system ensures the high quality of the product. Its durability ensures its prolonged working time

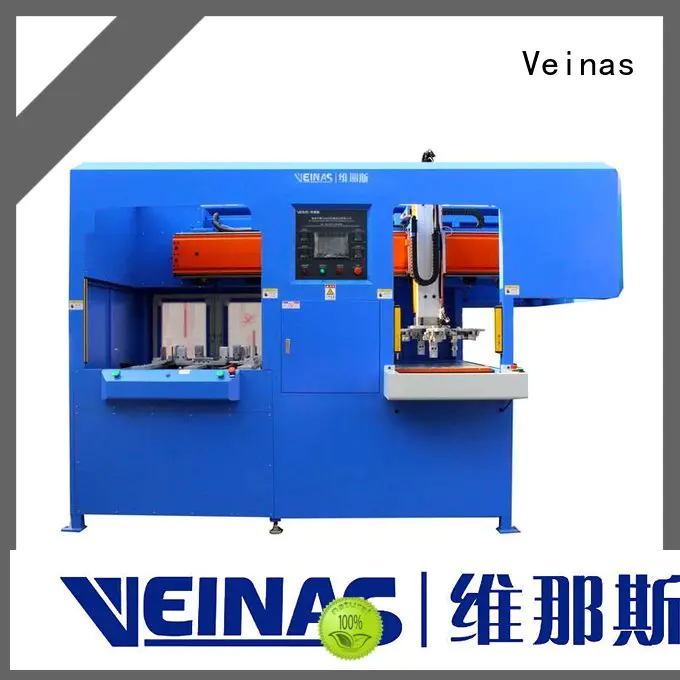

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

YXJH-5070 | 3300*1260*2350 | 500*700*200 | 22 | 10~11 | 1.5 |

YXJH-6080 | 3700*1370*2750 | 600*800*200 | 31 | 15-16 | 1.9 |

1

Applications

Automatically laminating irregular shaped EPE foam or EPE box, and widely used in air-condition and PC packaging.

2

Operation Principles

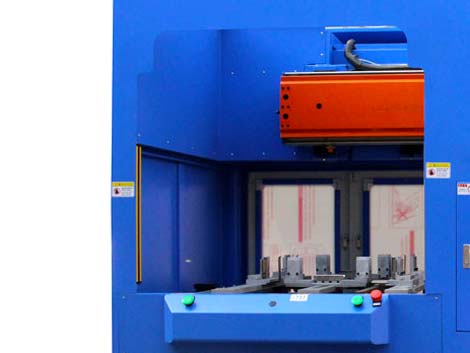

The vertical lamination is done by upward and horizontal movement of vertical ironing board as well as the laminating work-station fixture, and then the clamping jaw grips the laminated part and moves onto the horizontal ironing station for heating and laminating into the integrity.

3

Performance Advantages

Steadily running with the multi-axis servo control, and laminated at a time in different directions(vertical/horizontal) as to improve the production efficiency greatly.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has advanced production machines and modern production lines for roll to roll lamination machine .

2. That every part of the industrial laminating

machine manufacturers is strictly controlled more assures the exquisite performance of a product.

3. We are committed to increasing our market share in existing markets, investigating new product opportunities, and aggressively pursuing business opportunities in new markets.