Company Advantages1. Veinas has passed through the assessment regarding system design, waste characterization, chemical treatability, sludge dewaterability, and pH neutralization.

2. The functionality of the product has been significantly improved by our strong R&D team.

3. The product quality of hot wire

foam cutting machine use in construction industry is ensured for a better global competitiveness.

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

GSF-13050 | 3100*1900*2100 | 13.7 | 1300*500 | 8 | 6.5 |

1

Applications

Mainly used for hi-speed EPE slitting as to improve the production efficiency greatly.

2

Operation Principles

After setting the length and width by numerical control system, this machine could cut up to 500mm thick stacked EPE foam sheets with high speed.

3

Performance Advantages

1. Slitting up to 500mm thickness of stacked EPE sheets once, which greatly improve the production efficiency.

2. Easy operation with the numerical control system.

3. Adjustable slitting dimension available upon the demand.

4. Available for slitting both EPE sheet and EPE foam roll as well.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

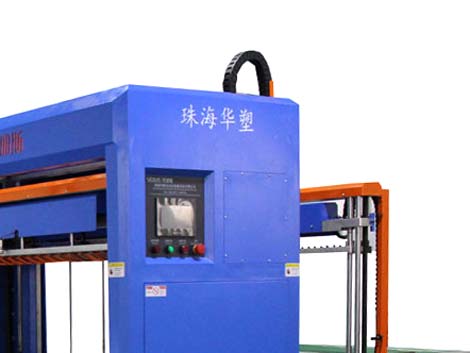

Company Features1. Being one of the most competitive companies specializing in the R&D, design, and production of , Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is widely accepted.

2. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd constantly improving its technology to produce better quality of hot wire foam cutting machine use in construction industry .

3. Veinas has the inspiration to safeguard and build our reputation. Call now! Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is committed to supplying satisfactory support to customers. Call now!