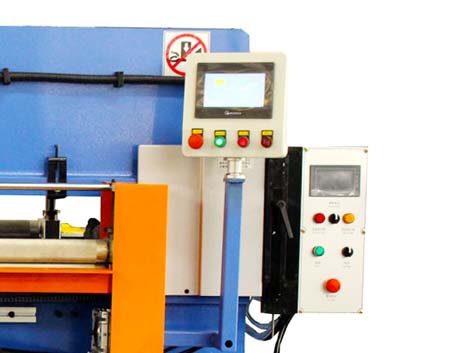

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

GSSY-60T | 60T | 2100*2200*1700 | 810*1400 | 5.5 | 50-240 |

GSSY-80T | 80T | 2100*2200*1700 | 810*1400 | 7.5 | 50-240 |

GSSY-100T | 100T | 2100*2200*1700 | 810*1400 | 7.5 | 50-240 |

GSSY-120T | 120T | 2100*2200*1700 | 810*1400 | 11 | 50-240 |

GSSY-150T | 150T | 2100*2200*1700 | 810*1400 | 11 | 50-240 |

High efficiency 36KW fuel or gas boiler

Introduction

The series full-automatic electric heating steam generator adopts copper high pressure submersible worm gear for water inlet. It is durable with short water supply time.The water tank is provided with liquid level floating ball to automatically control the water volume. The working system completely adopts automatic control. Within about 5 minutes after switching on the water source and power supply, it can continuously output steam with super high working efficiency.

Technical Parameter

| Model Number | JT-Y(Q) |

| Input Power Supply | Φ3380v |

| Input Power | 18kw/36kw |

| Steam Pressure | 0.25-0.4Mpa |

| Vapor Generation | 24kg/h 48kg/h |

| External Dimension | 600×550×1200 |

| Weight | 96kg |

Steam Generator

1.88% High effciency

2.NG / LPG gas fuel

3.Safety,easy remove

4.Long guarantee

Material sources of parts

Notes: A quality department has been set up to control the product quality during every process of production. For years, we are strictly implementing International Quality Management System ISO 9001.

Notes: Founded in 1997, with 5 production lines and covering an area of 12,000 square meters, our factory has developed into a professional manufacturer of cosmetics machinery and equipment, by integrating R&D, manafacturing, sales and service. Advanced production equipments are the guarantee for high quality products.

Notes: Our product catagories mainly include: Vacuum emulsifying mixer, Liquid washing mixer, Water treatment equipment, Perfume machine, Filling machine, Packing machine, Labeling machine etc. We are able to supply a wide range of high quality products for your One-stop sourcing in our exhibition center.

Notes: We are a professional sales team with high efficiency, and endeavoring to provide satisfactory services to every of our customers as always.

FAQ:

Questions one:How to operate the machine?We start to use the machine at the first time?

Answer:we have operation video and instruction book. also have engineer to users' company

Question two:How to repair or change when some parts are broken?

Answer: Factory will make fixed vide as the problems the users mentioned

Questions Three:How to Maintain the machine?

Answer:Maintain Manual will note how to do for users.

Questions four:How to choose the most suitable packing machine?

Answer:It depends on the weight to pack,products and bag type and bag's sizes

Questions five:What is MOQ?

Answer:1set

Questions six:How to pay for the machines?

Answer:T/T(30% in advance,70% balance is paid shipment);100% L/C at sight

Questions Seven:What is your delivery time?

Answer:20days after receipt of deposit

Questions Eight:How to ship the machines?

Answer: By sea or By air

Q:How can I contact you for further business relation?

Answer: Contact person:Phoebe Chen

Mobile: +86 -13822278408

Address: Building B1, Deli entrepreneurial Zone, Hebian Road, Baiyun District, Guangzhou, China.

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.