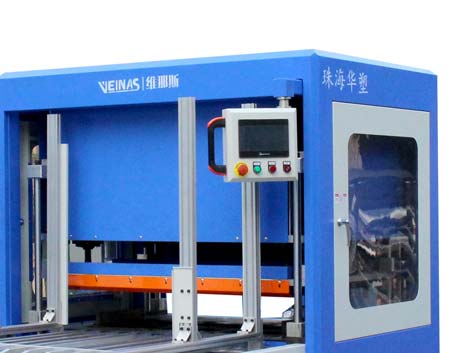

Company Advantages1. During the manufacturing of Veinas round hole

punching machine, the source of raw materials is secured. These materials are purchased from some of the most top grade suppliers with good reputation. This product can be customized to meet the specific requirements of customers

2. Due to the professional service, Veinas has won many attentions for now. It is much convenient and precise for users with touch screen function

3. The product has the advantages of strong durability, good performance, long lifespan, etc. The product owns patents on the design of appearance, practicality, and novelty

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

CXJ-6080 | 2200*1060*1900 | 3 | 800*600 | 1.5 | 1.5 |

CXJ-12065 | 2400*1560*2050 | 4 | 1200*650 | 2 | 1.8 |

1

Applications

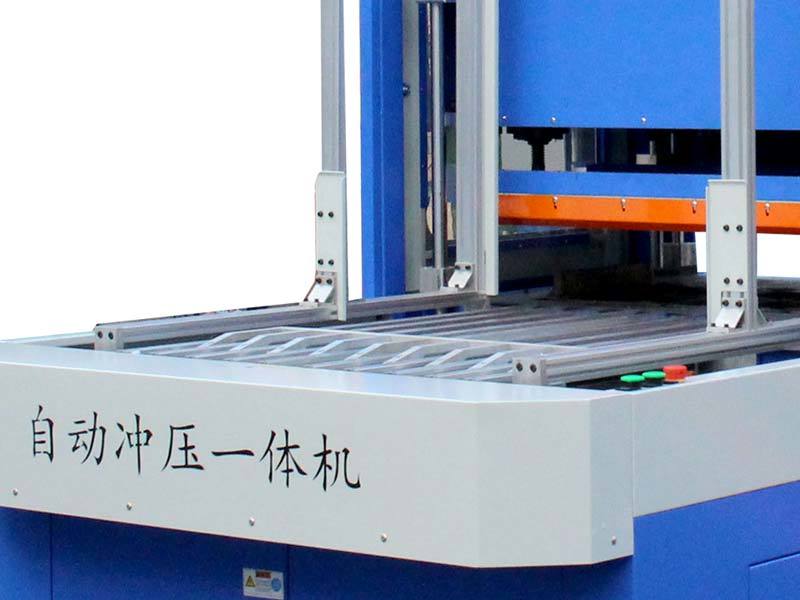

Successive feeding available, and one-time completion for cutting, punching and discharging at the same work-station.

2

Operation Principles

For long or rolled EPE, it could be done by a combination of continuously pulling, punching, cutting, and waste-discharging. In turn, the waste is squeezed out from the cavity of the die. Three processes are completed at one time with hi-efficiency.

3

Performance Advantages

Die-cut punching and waste-discharging into the integrated shape. Lowest labor intensity and highest production efficiency. Mainly used for EPE mass production.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd always grasps the market opportunity to create quality round hole punching machine. We have been recognized for strong competence in the industry.

2. Our hole punching machine is easily operated and need no additional tools.

3. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd constantly optimizes our service system and improve quality of EPE punching machine . Inquire!