Company Advantages1. Veinas roll to roll laminator is carefully developed. It is carried out by the R&D team who takes many factors into considerations such as radiated emissions, radiated susceptibility, ESD (electrostatic discharge), electrical transients, etc.

2. Modified by several times, EPE foam automation machine can be applied into many different places.

3. The product can reduce production costs. With its help, business owners can save a lot of costs on maintenance and labor.

4. This product will thus help to enhance people's work efficiency. Its automation makes many tasks easier and be finished faster.

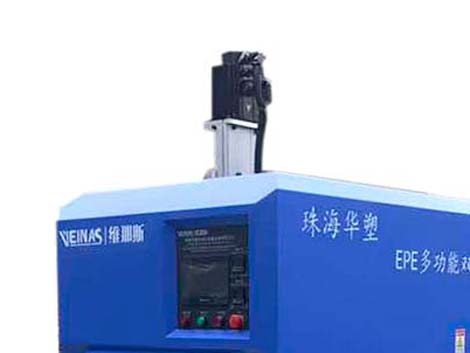

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly. Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension (mm) | Machining size(mm) | Gross Power(KW) | Power Consumption (KWH) | Net weight(T) |

VK-7050 | 2850*1000*2580 | 500*700 | 17 | 7-8 | 1.3 |

VK-9060 | 3470*1190*2650 | 600*900 | 25 | 11-12 | 1.4 |

VK-12065 | 3600*1460*2700 | 650*1200 | 29 | 13-14 | 1.7 |

VK-12080 | 4300*1460*2700 | 800*1200 | 34 | 15-16 | 1.8 |

VK-120110 | 5630*1540*2700 | 1100*1200 | 40 | 18-20 | 2.3 |

1

Applications

Mainly used for EPE lamination between the upper and lower layers, instead of traditional hot-air gun and hot-melt adhesive.

2

Operation Principles

The upper EPE layer is moved onto the ironing station for heating by the principal axis and burnt around 3mm for the instant lamination together, Instead of the tedious manual operation.

3

Performance Advantages

1.Steadily running with multi-axis servo control, imported electronic components and controller;

2.Easy maintenance;

3.Advanced equipment system and simple operation;

4.Safer and more stable.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. The rich experience and good reputation bring Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd a great success for EPE foam automation machine .

2. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd owns the largest and most advanced

automation equipment R&D center and laboratory in China.

3. We aim to gear our company to diversified markets. We will explore more new markets overseas and this will help our revenue sources keep stable by making up the difference. Undertaking social responsibility initiatives is truly a win for our company. We believe that true success comes when everyone focuses on the bigger picture and here, the bigger picture isn't just about manufacturing products—it's about trying to change the world for the better.