Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HS-HZ2 | 1090*1800*1600 | 700*250 | 17 | 5-6 | 0.6 |

HS-HZ4 | 2180*1800*1600 | 700*250 | 22 | 7-8 | 0.9 |

A3 Extrusion laminating machine price with CE / GSG

KMM-1050D/1220D High Speed Extrusion laminating machine, developed and produced collaboratively by Hangzhou Kangdexin and Italian leading laminating machine manufacturer Synergy, is multifunctional and efficient with top technologies. Its Max speed up to 90m/min makes it suitable for mass industrial lamination with various processes and material like OPP, PET and NYLON for a3 laminating machine price

a3 laminating machine price

Other products

Parameter

| A3 Extrusion laminating machine price with CE / GSG | |

| Model | KMM-1050D |

| Max.Sheet Size | 1050x820mm |

| Min.Sheet Size | 390x320mm |

| Suitable Paper Weight | 105-450g/m2 |

| Max. Working Speed | 40-85m/min |

| Max. Power | 80kw |

| Working Power | 35-45kw |

| Machine Weight | 9000kg |

| Overall Dimension(LxWxH) | 9000x2250x2800mm |

Extrusion laminating machine with CE GSG main features:

1. Specially coated cover makes the appearance more pleasant and elegant.

2. High quality feeder guarantees stable and efficient feeding.

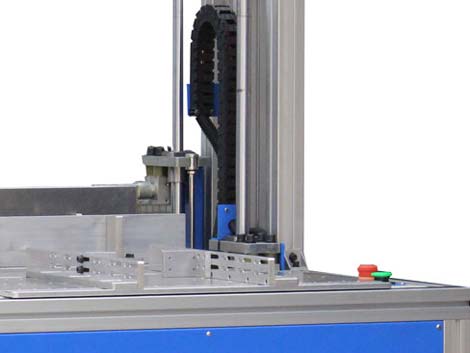

3. Servo-controlled overlap is more accurate and stable.

4. high accuracy intelligent homothermal heating system guarantees even temperature of heating roller.

5. Automation control system provided by global leading company.

6. Automatic film elevator reduces word load. The whole machine can be operated by only operator.

7. Separator equipped with thermal knife can cut all kinds of film.

8. Tension control system integrated in separator.

9. Contack of film and heating roller can be adjusted according to different speed and requirement.

10. More ergonomic designs make the machine more convenient to operate.

Our laminating machine is suitable for making laminating film materials in packing industry such as plastic-plastic, paper-

plastic and aluminum-plastic compositions.

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.