Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HS-30T1 | 30T | 2330*1320*1260 | 610*1600 | 2.2 | 50-160 |

HS-30T2 | 30T | 1950*1320*1260 | 610*1220 | 2.2 | 50-240 |

HS-30T3 | 30T | 2330*1320*1260 | 610*1600 | 2.2 | 50-240 |

HS-40T1 | 40T | 2330*1320*1260 | 610*1600 | 4 | 50-160 |

HS-40T2 | 40T | 1950*1320*1260 | 610*1220 | 4 | 50-240 |

HS-50T1 | 50T | 2330*1320*1260 | 610*1600 | 4 | 50-160 |

HS-50T2 | 50T | 1950*1320*1260 | 610*1220 | 4 | 50-240 |

Biomass briquette machine is one kind screw forming machine for recycling biomass materials and wastes into profitable briquettes as fuel use. The applicable raw materials can be any biomass materials from our agricultural production and forest area, like wood branches, sawdust, bamboo powder, corn stalks, rice husks. Processed by our briquetting press under high temperature and high pressure, these materials can be completely formed into high density briquettes with hexagonal or round or square cylinder shape briquettes. The finished biomass briquettes can be used directly in the stove. Besides, the finished wood briquettes can also be made into high quality charcoal briquettes through further carbonization by charcoal carbonizing furnace.

1.No binder during processing, pure fuel energy.

2. Special Alloy materials screw, wearing sleeve of the molding parts reducing the maintenance ratio.

3. Adopt the unique heating method to warm the machine in a short time 10-20 minutes and always keep the working temperature in a higher level.

4. Turnkey project design and proposal for the whole biomass briquette production line for new investors in charcoal/biomass briquetting production field.

5. A lot of successful cases at home and abroad can be for new clients references and visiting.

6. Supply on-site technical installation guidance for clients at home and abroad.

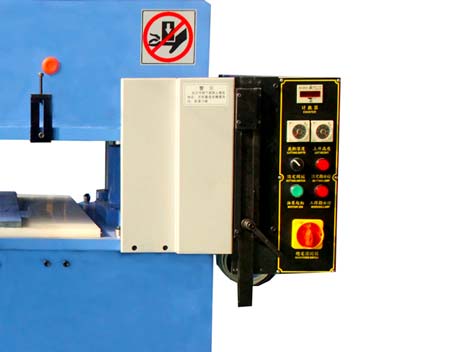

Electric controlling panel

Adopt digital screen in the electric controlling panel, be more easier to operate.

Plug and Socket

Special plug design to ensure safe and convenient operation.

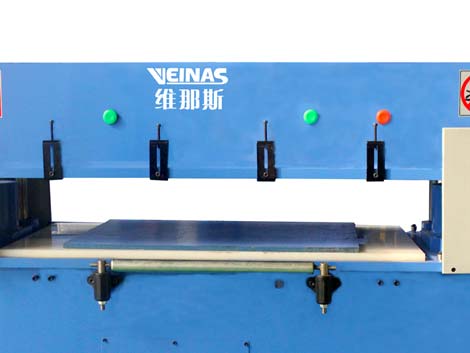

Cover of the machine

New designed cover of the machine to prevent the dust dropping down into the machine and protect workers.

Alloy materials screw

Special Alloy materials screw, wearing sleeve of the molding parts reducing the maintenance ratio.

| Model | HSZB50 | HSZB60 |

| Power | 15 | 18.5 |

| Heating power kw | 2x3 | 3x3 |

| Capacity kg/h | 200 | 240 |

| Finished briquettes size mm | 50 | 60 |

| Size mm | 1250x970x1080 | 1250x970x1200 |

| Weight kg | 600 | 730 |

Wood charcoal grinding machine

Mixer machine

Shisha machine

Zhengzhou E.P Machinery Co., Ltd. was established to provide our customers with easy access to the finest Chinese machines, such as Briquette Machines, Pellet Machines, Coal Machines and Corollary Equipment. Our staff members have rich experience in knowing about China, its people and its products and we are proud of ourselves for our commitment to quality, reliability and speed. This is made possible with our careful combination of expertise with rich domestic and overseas experience in both manufacturing and trading areas.Our MissionOur goal is to provide our clients with the best prices and make them return to us not only because of our competitive prices, but also because of our excellent quality machines and services.

1. We have a wealth of project experience and can provide complete technical guidance.

2. Provide integrated installation and complete guidance services

1. International Standard packing, Fumigation-free plywood;

2. Delivery time: 15~30 working days;

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.