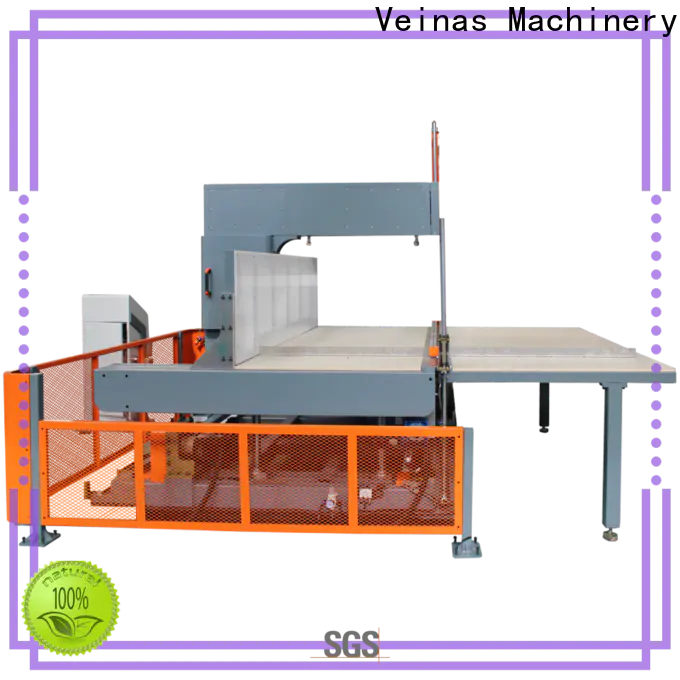

Polyethylene Foam Automatic Cutting Machine

Application

Applicable for all kinds of low density materials, such as EVA, EPP, XPE, EPE foam products, ect.

Performance

1. Less area occupied, space saving, more reliable.

2. By use of double-edged tools cutting, faster cutting speed and higher efficiency.

3. Via servo control, accurate positioning, more stability and more safety.

Working Principle

Mainly by use of PLC control servo motor, two-way reciprocating movement can do via the synchronous belt along with hi-speed rotary tools as to achieve the cutting purpose.

Pamameter

Video

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.