Company Advantages1. Veinas

foam sheet cutting machine has passed the necessary tests. They include operation safety testing, electromagnetic compatibility testing, vibration testing, reliability testing, and fatigue testing.

2. Built with high quality materials and designed to make the most of the amazing ergonomic design, it exclusively gives users the perfect writing and drawing space.

3. This product will not get affected under bright and scorching sunlight, heavy rains and storms, and other extreme weathers.

4. It guards operators against any dangerous or harmful operations or working conditions, which makes it extremely popular in various industries.

5. The product satisfies the needs of social production and brings enormous economic benefits by improving productivity and cutting costs.

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

F-1300Z | 2000*1033*1530 | 5.5 | 100-1300 | 3 | 1.1 |

F-1600Z | 2300*1033*1530 | 6 | 100-1600 | 3.5 | 1.3 |

1

Applications

Mainly used for the cutting of EPE sheet, mattress sheet instead of the traditional vertical-cutting machine.

2

Operation Principles

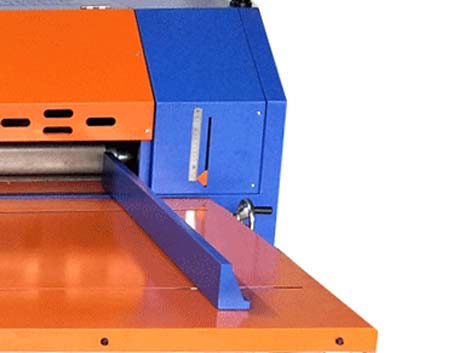

With PLC servo motor control, using our own designed variable speed control roller, to locate the length of the product to be processed.

3

Performance Advantages

1.Reliability and high precision with Mitsubishi PLC and Taiwan Weinview touch screen.

2.faster, cost-saving, less front edge and tail with electromagnetic clutch control for both upper and lower cutter.

Front edge is around 10mm, tail around 10mm compared to around 60-90mm for the similar equipment in the market. The cost around CNY¥300-2000 could be saved per day for the workshop.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is an export-oriented enterprise specializing in manufacture of EPE

foam cutting machine .

2. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd pays more attention to the technology of new slitting cutter products.

3. In the future, we will develop our own brands and innovate value-added products and services to enhance global competitiveness. Get more info! We have a clear and targeted aim for our company's future. We will work shoulder-to-shoulder with our clients and help them thrive on change. We will grow stronger through the challenges. We formulate plans on environmental protection, energy and resources conservation. We bring in infrastructure that mainly disposes of wastewater and waste gases. Besides, we will have strict control over resources use. We take environmental protection seriously. During the production stages, we are making great efforts to reduce our emission including greenhouse gas emissions and handle wastewater properly.