In the production process of EPE foam or expanded polyethylene faom packaging materials, physical foaming is used instead of chemical foaming. Currently, the most common foaming is using butane gas foaming. The principle of foaming is to use butane gas to be liquid in the jar, and then to gasify instantaneously when extruding from the foaming head. Because the foaming of EPE resin is the result of the physical foaming agent changing from liquid to gas, The second , foaming agent is required to be colorless, odorless, non-toxic, non-corrosive, no residue is left in the polymer after foaming, low permeability in the polyethylene melt, low vapor pressure at room temperature, high volatility, molecular weight Low density and high density. The gas cost per unit volume is low. It can be dissolved in polyethylene in the extruded state. When the temperature and pressure are increased, the amount of solubility will increase. It is easy to make the plastic foam molded into a foam with low density.

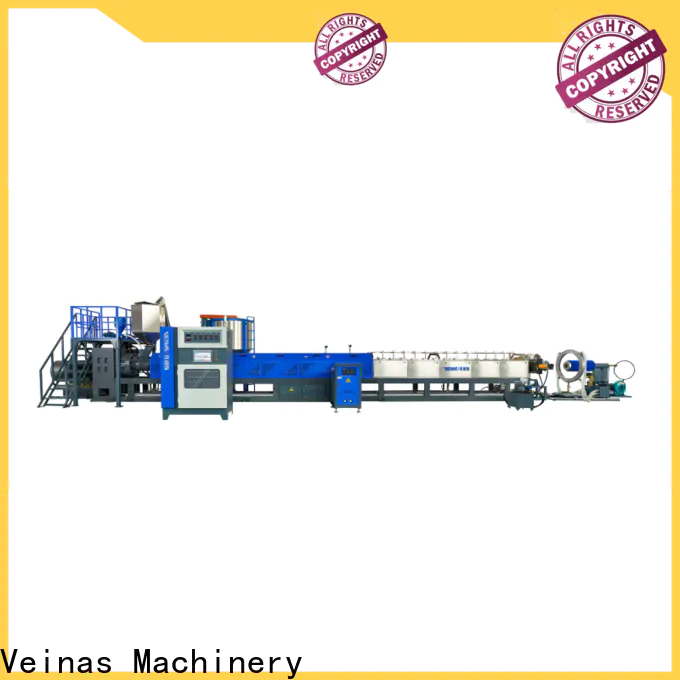

1. Main Technical Parameter:

Extrusion size (mm) | 90 | 105 | 120 | 135 | 150 | 180 | 200 | 220 | 250 |

Sheet thickness (mm) | 0.5 3 | 0.5 5 | 1 6 | 1.5 10 | 3 12 | 3 16 | 3 25 | 3 27 | 3 30 |

Max width (mm) | 1600 | 1600 | 1600 | 1600 | 2000 | 3000 | 4000 | 4000 | 4000 |

Production efficicy (kg/h) | 45 95 | 65 150 | 95 250 | 120 300 | 200 300 | 250 400 | 350 500 | 500 700 | 500 800 |

Capacity(KW) | 80 | 95 | 120 | 145 | 270 | 310 | 400 | 450 | 510 |

Power of main motor (KW) |

37 |

45 |

55 |

75 |

132 |

160 |

200 |

250 |

250 |

Power of traction motor(KW) |

1.5 |

1.5 |

1.5 |

1.5 |

2.2 |

2.2 |

2.2 |

2.2 |

2.2 |

Weight (T) | 6.5 | 7 | 8 | 9 | 10 | 12 | 15 | 18 | 22 |

2. Main streamline systems:

Serial Nr. | Name | Item | Specification |

1 |

Extrusion machine | Screw diameter (mm) | 90.105.120 135.150.170.180 |

Screw L/D ratio | 55 | ||

Speed-adjusting mode of drive engine | Frequency convertor | ||

Heater type | Far FIR or casted aluminum heater | ||

Heating zone and temp-controlled type | Zone 12 or zone 14automatic temp control | ||

Cooling method | Water cool | ||

2 | Butane pump

| Type | Horizontal bar plunger metering pump |

Rated flow L/H | 40.63.80.100.120.160 | ||

Exhaust pressure(Mpa) | <20 | ||

Motor power(Kw) | 3-4 | ||

3 |

Monostearin | Type | Horizontal bar plunger metering pump |

Rated flow L/H | 4.6.8.10.12 | ||

Exhaust pressure(Mpa) | <20 | ||

Motor power (Kw) | 0.7、1.1、1.5 | ||

Monostearin vol.(L) | 7 | ||

4 |

Machine head | Specification (mm) | 85-95 or Custom |

Heater type | Casted aluminum heater | ||

Heating zone& temp- controlled method | Zone 2 automatic temp-control | ||

Cooling type | Water cooling | ||

5 |

Shaping&cutting | specification of shaped device (mm) | 350-380or custom |

Wind loop diameter(mm) | 500-700 or custom | ||

Ventilator power of wind loop(Kw) | 0.75 | ||

Ventilator power of shaped device(Kw) | 0.55 | ||

Cutting motor power(Kw) | 0.18 | ||

Cutter diameter(mm) | 200-400 | ||

6

7 | Tractor

Winder | Traction roller diameter (mm) | 270-320 |

Traction motor power(Kw) | 1.5(speed-adjusting) | ||

Decelerator speed ratio | 15 | ||

Rolling method | One station cyclic reeling | ||

Torque motor capacity (Nm) | 10 | ||

Overturn motor power (Kw) | 0.55 | ||

Counting method | Automatic counter | ||

Max winding diamter(mm) | 1500 |

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.