Structural characteristics of foam cutting machine_upgrade of foaming machine

by:Veinas

2021-06-21

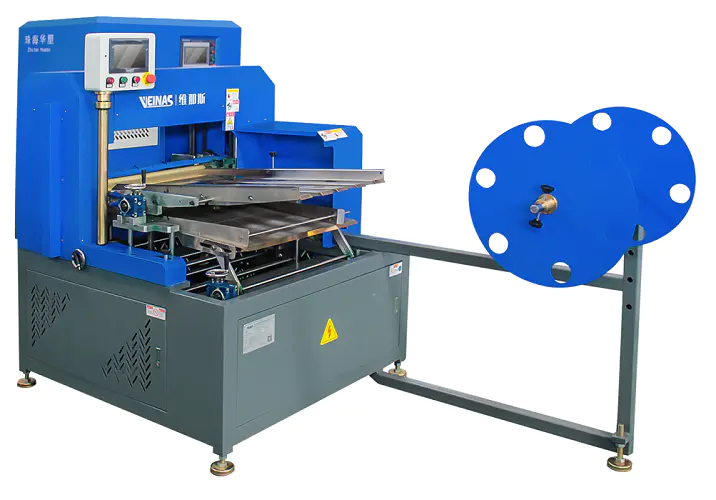

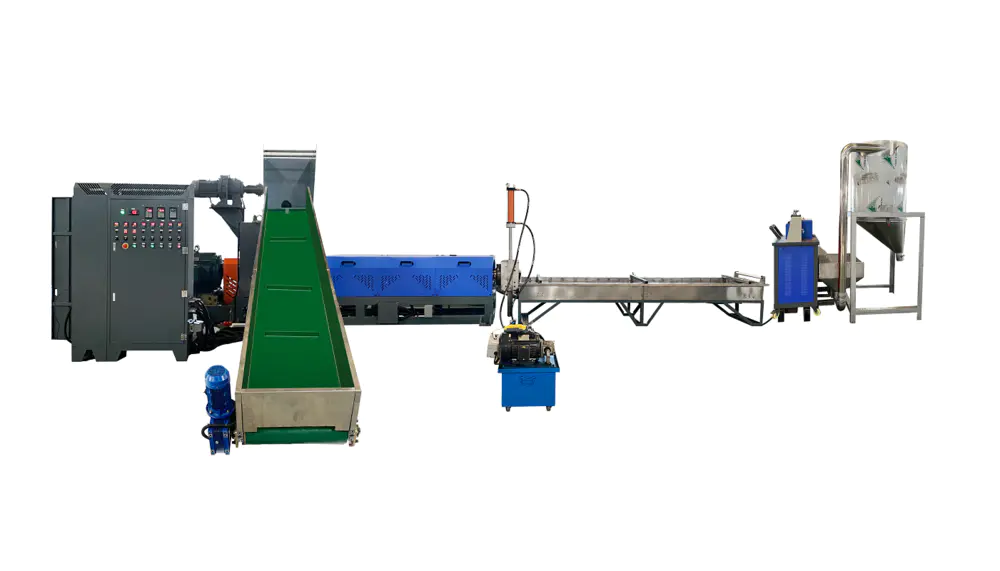

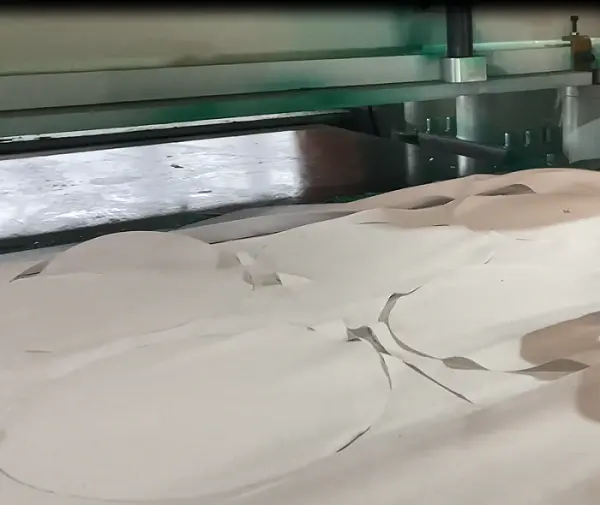

In the introduction to the structural characteristics of the foam cutting machine, we have learned some unknown problems or knowledge, but we are still relatively unfamiliar with the industry in which 'Huasu' is located. Today we will come to understand: Foam cutting The structural features of the machinery are as follows: 1. Equipped with a movable cutting and adjusting device. In order to ensure the size and accuracy of the cutting material, the machine is equipped with a digital display ruler. 2. The movable worktable adopts the suction method of negative pressure, and the cut foam can be fixed and not shifted randomly. 3. When the operation is stopped, it is equipped with manual and automatic devices. 4. The red brake button of the foam cutting machine is used for manual braking. When the start button is pressed, this button becomes invalid. When the brake electromagnets are attracted to each other, press the start button foam again, the structure feature of the foam cutting machine, the brake electromagnet releases immediately. Related article recommendation: Foaming machine first appeared in foreign countries. Its original model used impeller to rotate at high speed to make foam, so it is also known as 'foaming machine'. Later, with the continuous advancement of technology, the technical content of foaming machines continued to increase, new models continued to appear, and different technical systems were formed. my country started to use foaming machines as early as the 1950s, but instead of special foaming machines, mortar mixers were used. That is, the foaming agent is directly added to the mortar mixer or concrete mixer, and the foaming machine and the mortar or concrete are mixed together to generate foam. Later, around the 1970s, dedicated foaming machines, namely high-speed impeller foaming machines, began to appear. In the future, the technology has been continuously upgraded and replaced, and now it has developed into a third-generation model with high-pressure inflation as the main body, which can basically meet the needs of foam concrete. However, compared with foreign developed countries, my country's foaming machine automatic cutting machine process foaming machine upgrade degree is still relatively low, there is still a certain gap in foaming performance, and further improvement is needed. From the perspective of development trends, this gap is gradually narrowing and narrowing. The main advantage of my country's foaming machine at present is its low price. Most of the imported models are more than 100,000 yuan/unit, and the highest is 150-200,000 yuan/unit, while the domestic models are mostly tens of thousands of yuan/unit, and the simple and smallest models are even several thousand yuan/unit. They have certain advantages in price. Therefore, it is suitable for national conditions and is welcomed by most small and medium-sized enterprises. The content described in 'Structural Features of Foam Cutting Machine' was prepared by our editor meticulously for everyone. Remember what was said in the previous article? These may all be incomplete, and we will explain them one by one in future articles.

looking for the best deal while getting a quality is usually the number-one objective for most machine manufacturer manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd offers the best products, high-quality services and innovative technology.

According to the market analysts, exports from Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd facilities in China will exceed the forecast.

looking for the best deal while getting a quality is usually the number-one objective for most machine manufacturer manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd offers the best products, high-quality services and innovative technology.

According to the market analysts, exports from Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd facilities in China will exceed the forecast.

Custom message