Structural characteristics of foam cutting machine_foaming principle of foam machinery

by:Veinas

2021-06-21

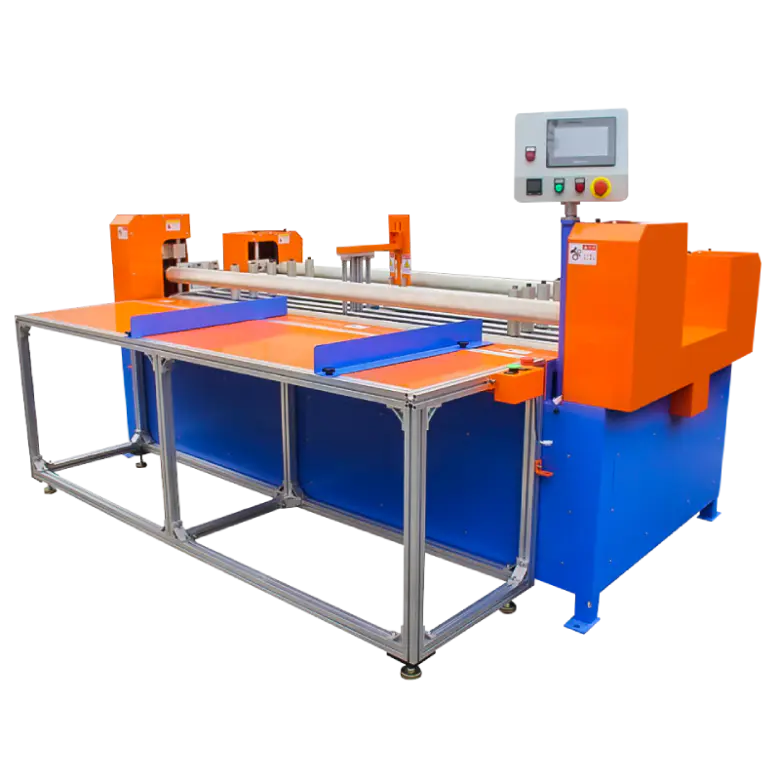

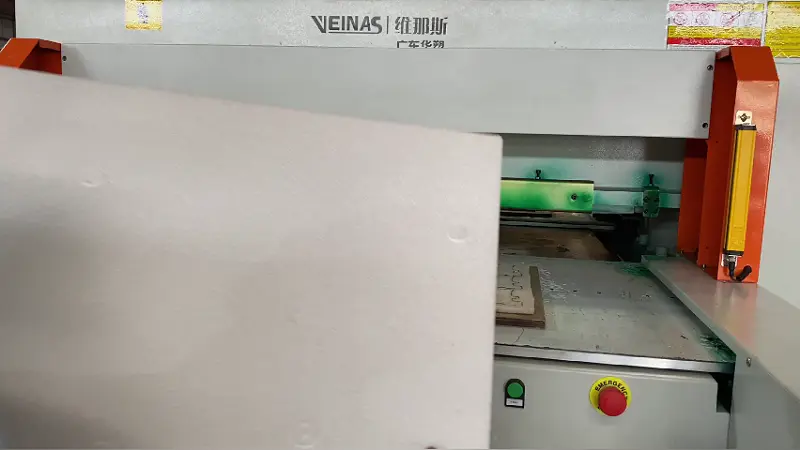

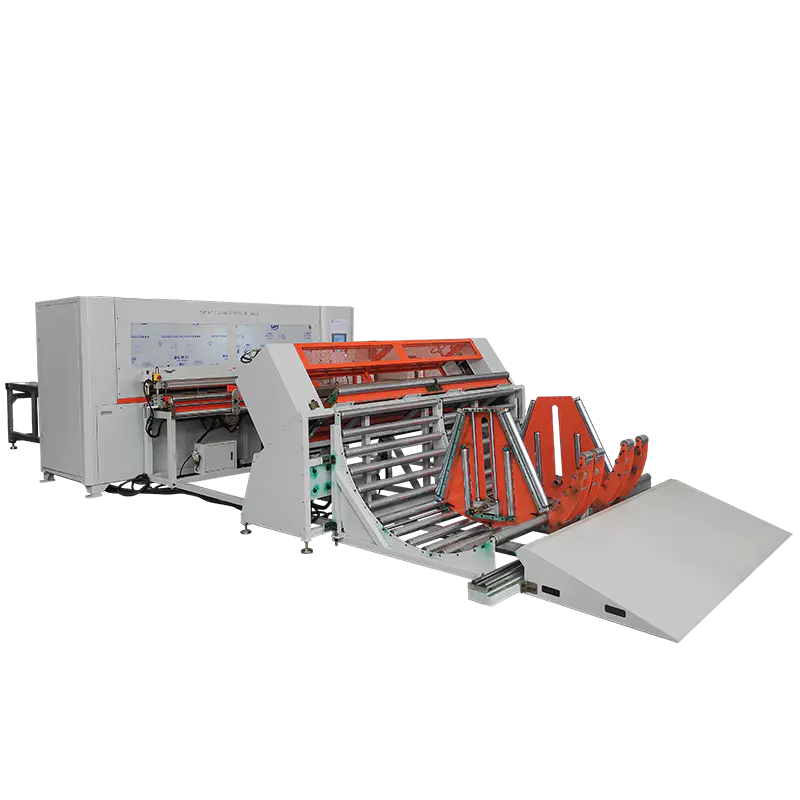

In the introduction of the structural characteristics of the foam cutting machine, we have learned some unknown problems or knowledge, but we are still relatively unfamiliar with the industry in which 'Hebei Guangxing Foam Machinery Co., Ltd.' is located. We will come today. To understand: The structural characteristics of foam cutting machinery are as follows: 1. Equipped with a movable cutting and adjusting device. In order to ensure the size and accuracy of the cutting material, the machine is equipped with a digital display ruler. 2. The movable worktable adopts the suction method of negative pressure, and the cut foam can be fixed and not shifted randomly. 3. When the operation is stopped, it is equipped with manual and automatic devices. 4. The red brake button of the foam cutting machine is used for manual braking. When the start button is pressed, this button becomes invalid. When the brake electromagnets are attracted to each other, press the start button foam again, the structure feature of the foam cutting machine, the brake electromagnet releases immediately. Related articles recommend: A certain amount of foaming agent and water vapor are retained in the beads of the foam machinery and equipment. The pressure drops quickly, negative pressure (partial vacuum) appears in the bubble, and the beads are very soft and easily deformed. Therefore, when air is sent, try not to make the wind pressure too large. The inner wall of the duct should be as smooth as possible, and the bending radius should be as large as possible (to reduce collision resistance). The pipeline should be a good conductor of electricity, and the entire line must be grounded to avoid static electricity. For ignition, the transmission speed should not exceed 8m/s to avoid damage to the beads. A certain amount of foaming agent and water vapor are retained in the pre-expanded beads of the foam machinery and equipment. When they are discharged from the machine, they will condense into a liquid, and the liquid foaming agent will dissolve into the polystyrene to quickly reduce the pressure in the bubbles. , There is negative pressure (partial vacuum) in the bubble, and the beads are very soft and easily deformed. Therefore, when the air is sent, try not to make the foaming principle of the air cutting machine press the foam machine too large. The inner wall of the air pipe should be as smooth as possible, and the bending radius should be as large as possible (to reduce collision resistance). The pipe should be a good conductor of electricity. Ground the entire line to avoid static ignition, and the transmission speed should not exceed 8m/s to avoid damage to the beads. The beads just out of the foam mechanical pre-expander are all damp. After being released from the pre-expander, they absorb air and suddenly encounter cold, causing the foaming agent in the honeycomb cells to condense and form a negative pressure in the cells, so the beads are in It must be placed for a period of time after pre-expansion. On the one hand, it is dried, and on the other hand, it is allowed to infiltrate air to eliminate negative pressure, so that the internal pressure and external pressure in the cells are balanced, so as to prevent the cells from collapsing and make the beads elastic. The process of drying, cooling and stabilizing the cell pressure of the EPS beads just out of the pre-expander is called maturation. Maturation improves the further expansion of the pre-expanded beads during the molding process, the fusion between beads and the elasticity of the beads, which is beneficial to improve the quality of EPS products. Through the introduction of this article, I believe everyone has a certain understanding of the 'structural characteristics of foam cutting machine'. If you want to know about the real gold board production line, real gold EPE foam machine, Hebei Guangxing Foam Machinery Co., Ltd. and other related knowledge, please follow Contact us!

come in many forms, like machine manufacturer and machine manufacturer, and they all provide efficient solution for our machine manufacturer needs.

We are dedicated to providing you with more than just customer service by utilizing our qualified team who pride themselves on meeting and exceeding customer's needs. We also have ell-equipped plantin China with advanced facilities to manufacture machine manufacturer automation equipment manufacturer products according to customers requirements. Welcome to send your enquiry and visit our factory. Our website is Veinas Machinery.

Data has always been important in business, of course. But with the arrival of digital data—its volume, depth, and accessibility—it has become clear it is key to helping Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd develop sustainable competitive advantage.

We focus on operational procedure and manufacturing facilities of automation equipment manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd can promise you that we never conceded on the quality standards of our products.

come in many forms, like machine manufacturer and machine manufacturer, and they all provide efficient solution for our machine manufacturer needs.

We are dedicated to providing you with more than just customer service by utilizing our qualified team who pride themselves on meeting and exceeding customer's needs. We also have ell-equipped plantin China with advanced facilities to manufacture machine manufacturer automation equipment manufacturer products according to customers requirements. Welcome to send your enquiry and visit our factory. Our website is Veinas Machinery.

Data has always been important in business, of course. But with the arrival of digital data—its volume, depth, and accessibility—it has become clear it is key to helping Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd develop sustainable competitive advantage.

We focus on operational procedure and manufacturing facilities of automation equipment manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd can promise you that we never conceded on the quality standards of our products.

Custom message