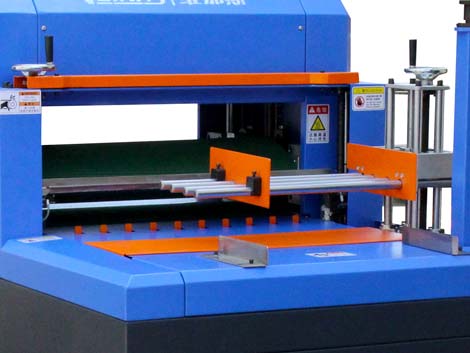

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

RFJ-7050 | 2625*1900*1200 | 700*500 | 13 | 8 | 1.4 |

China manufacturer 10 years experience sensible CNC driller

China Manufacturer 10 Years Experience Sensible CNC driller

General description

JPZ160A digital control driller employs AC servo motor to drive the X axis and Y axis ,while its Z axis is positioned by high accuracy raster ruler.By using semi-closed closuer digital control system,the machine has reliable performance.The operation of the machine can either be automatic or manual.This machine is widely used in steel frame consruction.

Technical parameter

| Item | Parameters |

| Drilling diameter | Φ50 |

| Max.dimension of workpiece | 1650*1000*80 |

| Rotary speed of main shaft | 130-400r/min,Stepless and adjustable |

| Feeding type of main shaft | Hydraulic |

| Quantity of moveable working platform | 2 |

| Workpieces can be toolde for once | 4 group |

| Clamping type | Hydraulic |

| X and Y axis fast moving speed | 12m/min |

1.Does one machine can only produce one size?

Not exactly, it depends on the machine.

2.Do you have after sales support?

Yes, we are happy to give advice and also have skilled technicians available to maintain the machine if needed.

3.How to visit your company?

We can pick you up from Shanghai or Hangzhou airport. Or railway station Shaoxing North.

4.What can you do if the machine broken?

Our machine's warranty period is 12months. if the broken parts can't repair, we can send the new parts replace the broken parts, but you need pay the express cost by yourself. if after warranty period, we can through negotiation for solving the problems, and we supply the technical support for the whole life of the equipment.

5.Can you be responsible for transport?

Yes, please tell us the destination port or address. we have rich experience in transport.

6.You are trade company or factory?

We are Manufacturer.

7.Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our machine could use more than 20 years without any problem.

8.Do you have overseas engineers?

Yes, we not only provide overseas engineers, but also provide technical training.

9.Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide. We are professional sheet metal forming machine designer and manufacturer.

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.