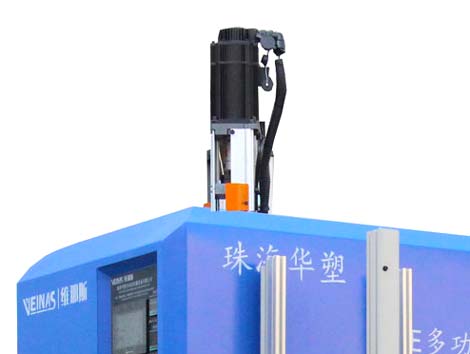

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

QJC-7050 | 3230*2150*2350 | 500*700 | 17 | 8 | 3.5 |

Product description:

This machine is mainly used for producing soft polyurethane foam with spring holes,

and the density is 10-50kg/m3. The combination of the foam with built-in pocket spring (or bonnel springs) shows the best advantage of them. Displaying it’s unique and best figuration, air permeability, and comfortable! The hardness and softness is controllable, it is the best choice for the production of high-grade mattress, sofa cushion!

This machine consists of a storage system, the quantitative feeding system, mixing

system, molding box, demolding device with Teflon coating, unloading transportation,digital controlling system. The production process is full automatic, is easy to operate.

Specifications:

Output | 1 block / 5 min |

Foaming density | 10—50kg/m3 |

Mixing speed | ≤2200rpm |

Flat top foaming | With flat top device (Square block) |

Mould sizes | 2050x950 x 600mm (2 sets) |

Total power | 20KW |

Overall dimension | 4600mm(L) x 3360mm(W) x 2500mm(H) |

Payment term:

1.L/C at sight.

2.T/T:30% deposit by T/T ,70% balance by T/T before shipment.

3.Western Union.

4.Trade Term: EXW,FOB Jiangmen,CFR.

Packing detail:

1.Pearl wood and PVC film.

2.All of the productions are inspected carefully by QC before delivery.

Delivery time:

By T/T within 45 days after receive 30% deposit

Min.Order: 1 set.

FAQ

Q:Are you a trading company or a manufacture factory?

A:We are manufacture factory which is professional for foam machinery,mattress machinery.

Q:What is your website?

A:Our website is:www.softlife88.com.cn.

Q: How about after-sales service and machine service?

A: Softlife Mattress Machinery Co.,Ltd will send professional engineers to final customer’s factory for machine installation , commissioning and carefully working training . The final customer will afford related cost .

Q: This is the first time I use this kind of machine, is it easy to operate?

A:We will send you manual and guide video, it can teach you how to operate the machine. If you still can not learn how to use it, we can talk by phone, email or other contact ways such as wechat ,whatsapp and etc.

Q: If there are some problem occur in my place, how could I do?

A:We could send parts to you if machines have any problem.You can also contact us,then we will guide you until the machines in normal operation.

Q:What is the warranty and quality of this machine?

A:Warranty normally 1 years.

Q: What's the package?

A: PVC Film packaging+wooden case,or PVC Film+container(according to customer’s requirements.

Q: What is the shipping cost from China to my country?

A: It depends on the distance between you and the sea port. We offer door to door service as long as you pay the relevant cost. For the shipping cost you can ask for our advice or from the freight forwarder.

Q: Where is your factory located? How can I get there?

A: Our factory is located in Taishan,Jiangmen City, Guangdong Province,China. You can fly to Baiyun Airport,Guangzhou City,then take a Airport Express to Taishan. We can pick you up at Taishan Airport Express Station.

Q: Is there any after sales service?

A: We have integrated after sales service. Besides our own experienced engineers, we also offer local after sales service through the help of our agents. All this will make you convenient.

1 Professional and patient consulting service to help you find the suitable solution.

2 Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3 Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4 Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5 Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6 For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7 For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that.

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.