Company Advantages1. Veinas foam lamination process has various high-quality, eye-catching designs.

2. The feature of automation machinery is foam lamination process , which is worthy of popularization in application.

3. foam lamination process makes the automation machinery more effective during the process of use.

4. That Veinas paying close attention to the quality assurance turns out to be helpful for its development.

5. The customers speak highly of the quality of automation machinery made by Veinas.

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HS-HZ2 | 1090*1800*1600 | 700*250 | 17 | 5-6 | 0.6 |

HS-HZ4 | 2180*1800*1600 | 700*250 | 22 | 7-8 | 0.9 |

1

Applications

It is optional for two-work-station or four-work-station. Dimension of EPE foam is adjustable for box-making processing upon the requirements.

2

Operation Principles

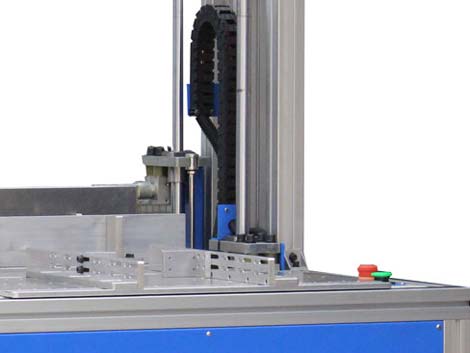

Putting the EPE foams in the fixtures in the same direction. One side moves to the vertical ironing plate for heating by the fixture after the upward ironing plate is heated, and instantly laminate together with another one for the box-making completion.

3

Performance Advantages

1、Control by servo motor, easy to operate;

2、High precision, suitable for produce all kind of high-class EPE foam box;

3、Easy to operate, heating plate away from operator which will be safety;

4、Working efficiency is much higher than made by manual.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has its own advantage to make automation machinery with top quality.

2. We have a professional R&D team that is supported by state-of-the-art technology development centers. This team is passionate about new product development and updating the existing products.

3. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd will spare no effort to satisfy the increasingly rich consumer demand for professional laminator . Contact us! Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd adheres to the corporate tenet of 'Quality First, Customer Foremost'. Contact us!