Specializing in the production of polystyrene board equipment, have you gotten skr

by:Veinas

2021-07-09

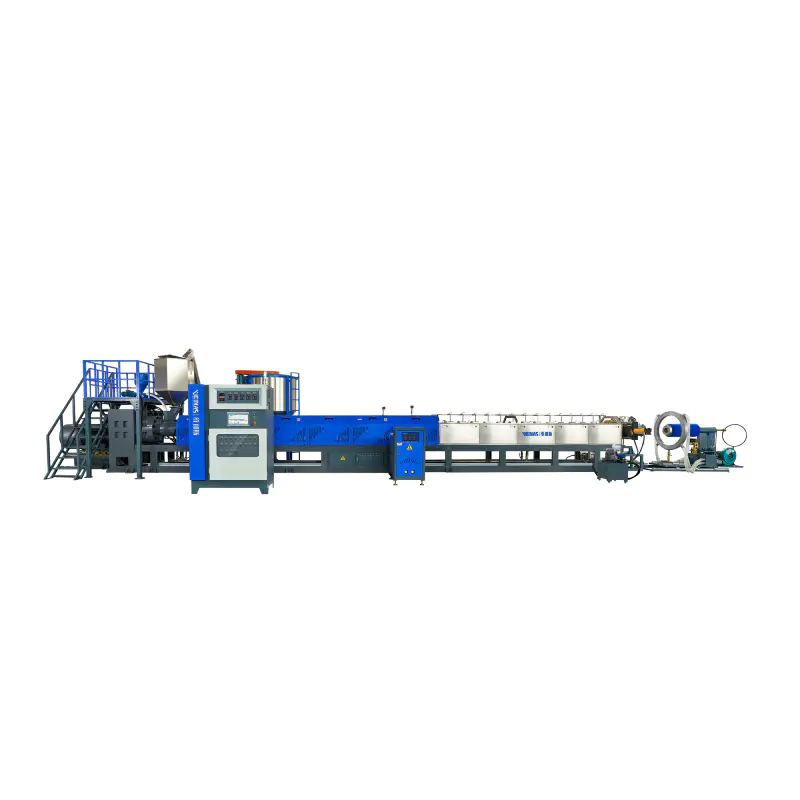

Class A siliceous polystyrene board equipment (silicon modified polyphenyl board) is a new type of thermal insulation material that is improved on the basis of traditional polystyrene board to achieve Class A flame retardant effect. It not only continues the advantages of traditional polystyrene boards such as low thermal conductivity and good thermal insulation effect, but also makes up for the disadvantages of poor flame retardant effects of traditional foam boards. It is a new type of ideal thermal insulation material that has a wide range of market needs. The principle of the EPE foam machine: the high pressure penetrates the flame-retardant liquid into the benzene board, and the solid is left in the benzene board after drying and aging to achieve the effect of weight gain and flame retardancy. It does not affect the physical properties of the benzene board, and improves the fireproof performance of the polystyrene board. 1. Good heat preservation and energy saving effect: The siliceous modified polystyrene board continues the traditional EPS foam board's advantages of low thermal conductivity and large heat storage coefficient. It has better heat preservation effects than inorganic active thermal insulation mortar and foam glass on the market. 2. Safe and fireproof—Class A flame-retardant material: The production line of siliceous modified polystyrene board overcomes the flammability shortcomings of traditional EPS foam board and has very high safety performance. It fully meets the Class A fire protection standard of insulation materials specified in the Gongtongzi [2009] No. 46 document jointly issued by the Ministry of Housing and Urban-Rural Development. 3, Class A fireproof EPS insulation board has higher strength than rock wool and phenolic board, does not absorb water, does not fall off, and is easy to construct. 4. Superior system performance: The siliceous modified polystyrene EPE foam machine is a closed and foamed spherical molecular structure, relatively light in weight, good in dimensional stability, and non-toxic. After water circulation and 30 heating-refrigeration cycles, there was no blistering, hollowing and shedding of the decorative layer, no water seepage cracks, and the impact resistance of the tiles reached 10J, and the impact resistance coating reached 10J, which was superior in performance. 5. Superior cost performance: The traditional EPS foam board retains the advantages of 'low thermal conductivity, good insulation effect, and mature technologyThe price obtains the A-level flame retardant effect, the cost performance is superior, and the market prospect is broad. Therefore, our EPE foam machine is still relatively popular in our architectural decoration. It can help us solve the problems of heat preservation and flame retardancy, and make our decoration easier.

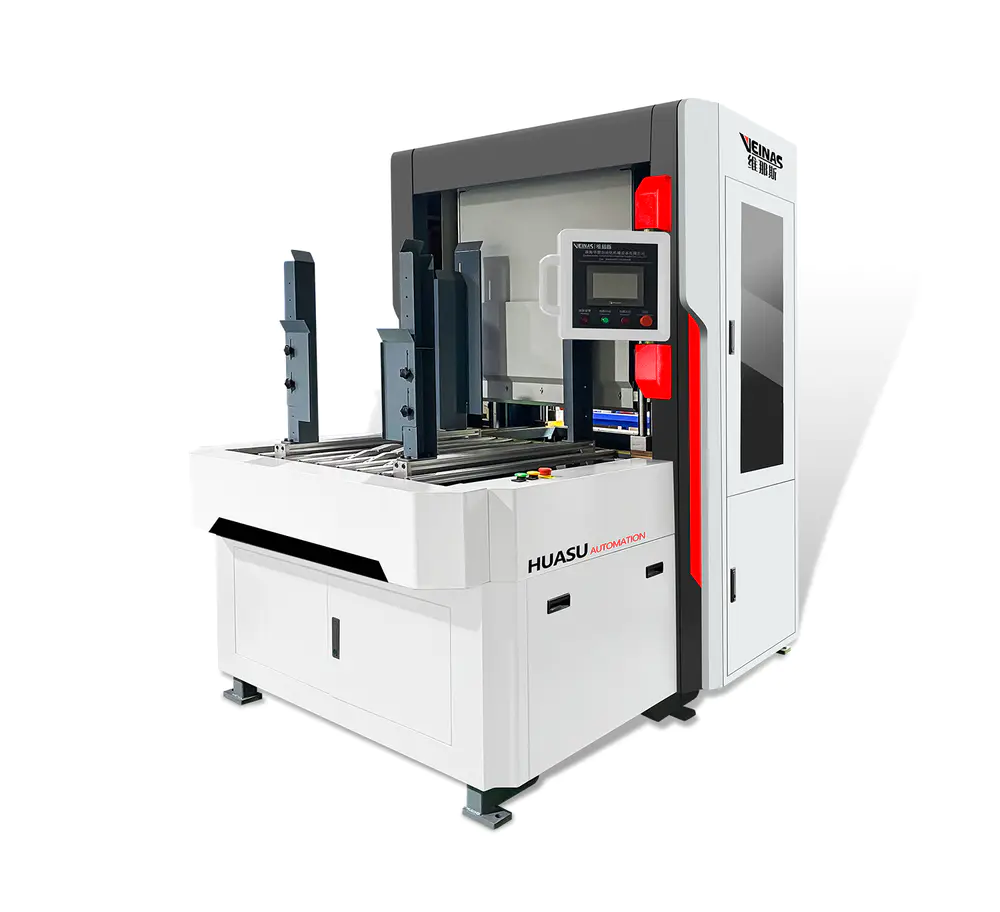

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's has been able to achieve excellent performance in an extremely competitive industry.

If you are looking for a reputable automation equipment manufacturer machine manufacturer, you are on the lucky side as we are among the leading supplier in China. Visit the given links Veinas Machinery to know more.

If something seems too good to be true, then it can be a , which provides machine manufacturer value over its cost.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's has been able to achieve excellent performance in an extremely competitive industry.

If you are looking for a reputable automation equipment manufacturer machine manufacturer, you are on the lucky side as we are among the leading supplier in China. Visit the given links Veinas Machinery to know more.

If something seems too good to be true, then it can be a , which provides machine manufacturer value over its cost.

Custom message