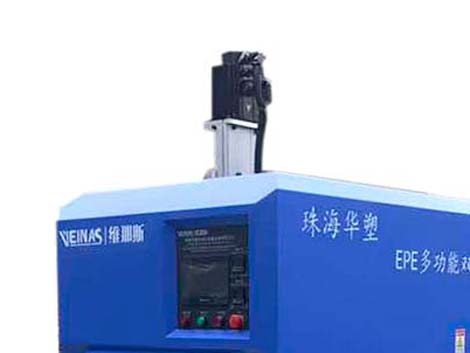

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly. Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension (mm) | Machining size(mm) | Gross Power(KW) | Power Consumption (KWH) | Net weight(T) |

VK-7050 | 2850*1000*2580 | 500*700 | 17 | 7-8 | 1.3 |

VK-9060 | 3470*1190*2650 | 600*900 | 25 | 11-12 | 1.4 |

VK-12065 | 3600*1460*2700 | 650*1200 | 29 | 13-14 | 1.7 |

VK-12080 | 4300*1460*2700 | 800*1200 | 34 | 15-16 | 1.8 |

VK-120110 | 5630*1540*2700 | 1100*1200 | 40 | 18-20 | 2.3 |

Copyright 2018 Zhuhai Huasu | All Design Rights Reserved by www.veinasmachine.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.