Scope of application of eps building module equipment_eps foam building module equipment market quotes

by:Veinas

2021-08-16

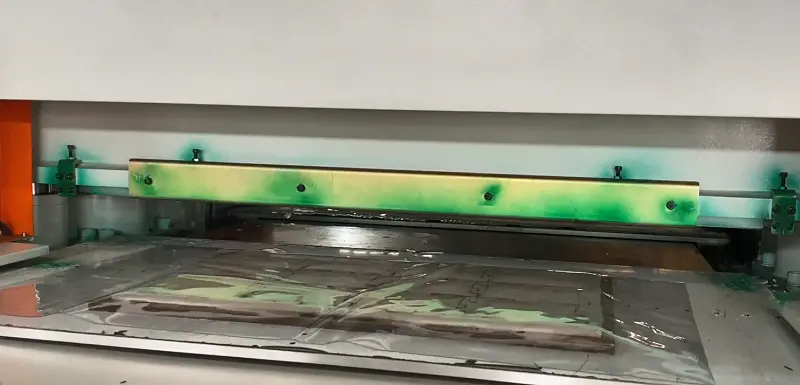

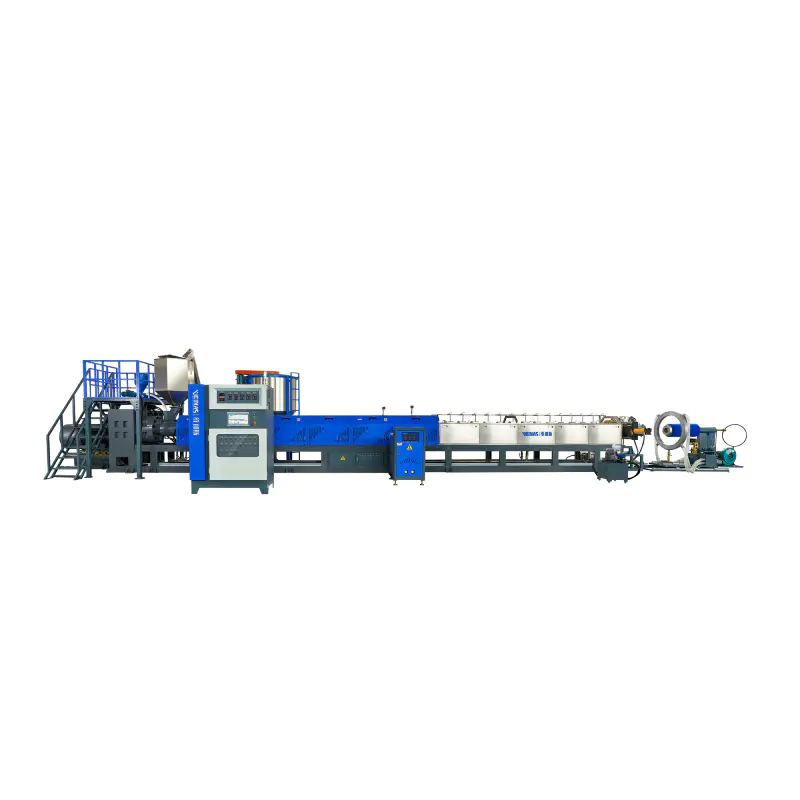

Hebei Guangxing Foam Machinery Co., Ltd. is a company specialized in real gold plate production lines, and its field is also quite prominent. Today we can find out the details of the company. The eps building module equipment is controlled by a computer. A machine capable of cutting any two-dimensional products from extruded and expanded EPS foam. Through the use of a computer-controlled step motor, the heating wire is cut in the X, Y and Z directions, which can make the foam material cut quickly and accurately. The principle of the eps building module equipment is to convert the CAD model of the product design to the HPGA format, and the computer-controlled micro stepping motor in the X, Y, and Z directions drives the processing tools-electric heating wire and profiling electric heating wire to cut EPS foam plastic materials , To obtain a two-dimensional EPS foam model. It has the advantages of fast processing speed, high forming accuracy, good surface quality, eps, eps building module equipment applicable scope and low manufacturing cost. eps building module equipment is suitable for machinery manufacturing, casting, automobiles, ships, industrial design, mold manufacturing and processing, advertising, architectural decoration and decoration, foam cutting plants, foam manufacturing plants, foam molding plants, school institutions, advertising production companies, packaging plants, Exhibitions, model factories, POP crafts processing and publicity display industries. More people like: The production process of eps foam building module equipment has great energy-saving potential. Taking injection molding machine as an example, the process of injection molding machine is generally divided into clamping, injection, melting, holding pressure, cooling, and mold opening. Wait for several stages, each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide the appropriate oil pressure for the eps foam building module equipment market at various stages of injection molding machine production, greatly reducing energy loss. As early as some end users who used frequency converters in eps foam building module equipment, system integrators provided them with a frequency conversion energy-saving transformation program for eps foam building module equipment, which has achieved remarkable results, so more and more eps foam building module equipment users They used frequency converters to transform their equipment. The above is a brief introduction about the 'eps foam building module equipment market'. Our company also has a real gold plate production line, Hebei Guangxing Foam Machinery Co., Ltd. and many other related products. If you are more interested, you can contact us for more Details!

Custom message