Company Advantages1. The tech pack of Veinas offered by customers greatly provides a solid foundation to get production started and helps to minimize errors in the production process. Its environmental friendliness helps to save much cost

2. The product helps improve the flexibility of working and production. It allows operators to change the operation tasks while it is in motion. The imported advanced components and controller ensure its stable performance

3. The product has a precise dimension. After it is produced, it will be checked using the dimension measuring equipment or coordinate measuring machine. The product features a large information storage capacity

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

GSF-13050 | 3100*1900*2100 | 13.7 | 1300*500 | 8 | 6.5 |

1

Applications

Mainly used for hi-speed EPE slitting as to improve the production efficiency greatly.

2

Operation Principles

After setting the length and width by numerical control system, this machine could cut up to 500mm thick stacked EPE foam sheets with high speed.

3

Performance Advantages

1. Slitting up to 500mm thickness of stacked EPE sheets once, which greatly improve the production efficiency.

2. Easy operation with the numerical control system.

3. Adjustable slitting dimension available upon the demand.

4. Available for slitting both EPE sheet and EPE foam roll as well.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

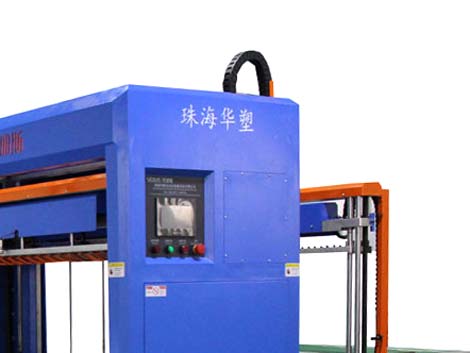

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is an economic power in epe foam cutter and presser field with its own powerful manufacturing capability. The factory has brought in advanced production machines. The machines feature high reliability, precision, and guarantee production efficiency. They give us strong confidence to offer timely delivery and ensure less defective rates.

2. We have a professional sales team. Combining their years of experience, they are able to communicate with our customers and distributors to ensure that our products, services, and solutions are targeted to their needs and exceed their expectations.

3. The factory operates under the 5S management method and is ISO9001 certified. This enables us to establish an integrated qualified manufacturing process in product development, design, manufacturing, quality control, packaging, and shipping. Veinas is a brand which adheres to the customer first principle. Ask!