Company Advantages1. Veinas

foam sheet cutting machine has gone through the following production stages. They include the approval of drawings, the fabrication of sheet metal, welding, the arrangement of wire, and dry run testing.

2. Among the main requirements of foam cutting

machine manufacturers , foam sheet cutting machine determines its future commercial feasibility.

3. foam cutting machine manufacturers is widely polulor around the world.

4. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd provides professional sales support for local partners and key accounts.

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch. Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

HSC-03 | 2405*1050*1550 | 8 | 100-1300 | 5-5.5 | 2.5 |

1

Applications

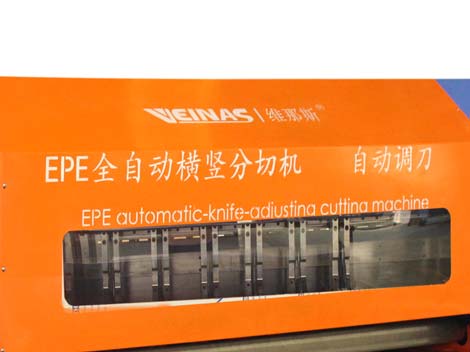

Mainly used for cutting EPE sheet horizontally and vertically along with the mattress sheet. The tooling is automatically adjusted instead of the traditional manual tooling adjustment.

2

Operation Principles

Configurating the required machining dimension by PLC servo motor, and locating the length by our patented variable speed controlling roller.

3

Performance Advantages

1.Instead of adjusting knifes by manpower, it could adjust knifes automatically, which greatly improves the production efficiency and makes the operation more easier.

2.Using Mitsubishi PLC from Japan and Weilun touch screen from Taiwan, which operates steadily with high precision.

3.Controlled by Electromagnetic clutch, the cutting speed is much faster.

4.It could reduce the wastage of the front and tail edging material. The wastage of this machine is about 10mm for both the front and tail edging material, but the wastage of similar machine in the market is about 60-90mm.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd, engaging in the development and manufacture of foam sheet cutting machine for many years, is gradually taking the lead in this industry.

2. A considerable manufacturing capacity has formed in Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd.

3. We are working hard to conduct our sustainability practices. We are considering environmental factors in our product innovation process so that every product is up to environmental standards. We are working hard to become an innovative leader in this field. We will invest more capital and talent resources in cultivating our R&D team to continuously promote technological innovation.