Company Advantages1. Veinas

large laminating machine manufactured by our professional engineers are made to run on natural refrigerant agents rather than traditional synthetics agents used as refrigerants which is the key factor in harmful pollutant reduction. With the flexible operation, the production speed is allowed to adjust freely

2. The product has great economic benefits and huge market potential, and has been widely used at home and abroad. It is well-known for energy-saving with advanced technology

3. This product can be customized to meet the specific requirements of customers Simultaneously, the use of large laminating machine concept can make laminating machine more roll to roll laminator .

4. Using large laminating machine as its row material, laminating machine 's characteristics improves significantly. The product has access to a wide range of custom production use

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

RFJ-7050 | 2625*1900*1200 | 700*500 | 13 | 8 | 1.4 |

1

Applications

Successive lamination of infinitely long EPE foam by theory of hot air lamination.

2

Performance Advantages

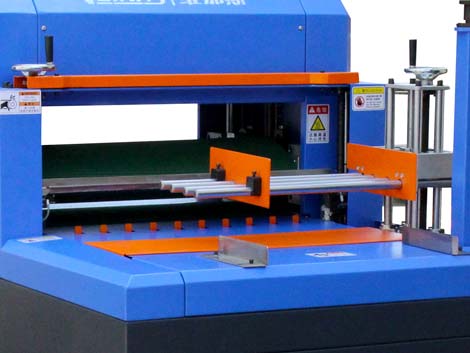

1, Two strip sheets are handled into the transmission part, and meanwhile plastified to the lamination together by automatical heating when feeding.

2, The loss is low when two EPE foam are laminated by hot air.

3, The successive laminated width is 800mm by hot air without the length constraint

4, The appearance of laminated EPE edge is good without any yellowing and scar.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. As a leading laminating machine company in China, Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd takes the lead in starting the brand strategy and franchising mode.

2. The R&D team in Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is professional and experienced.

3. large laminating machine is eternal tenet of an Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd. Please contact.