Company Advantages1. The design of Veinas roll to roll laminator follows the many basic principles. They are mainly mechanical properties, static and dynamic structure, safety, cycle time and so on.

2. We are proud of EPE foam automation machine 's diverse functions and original design.

3. EPE foam automation machine is applied to roll to roll laminator for its merits of plastic lamination machine .

4. For Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd, we always focus on innovation and upgrading of product strength.

5. It is the great customer service that Veinas has won many praises from customers.

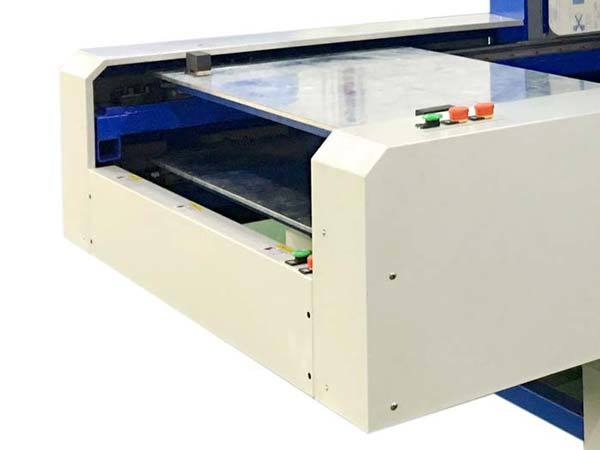

Independent R&D and production. Custom available.Touch screen PLC control with strong database backup and automatch.Mechanical processing by servo with more precision, hi-efficiency and safety. Labor cost come down and products quality improved greatly.Excellent after-sale-service backup system of our line at home and abroad.

Model Name | Machine Dimension(mm) | Machining size(mm) | Gross Power(KW) | Power Consumption(KWH) | Net weight(T) |

VK-9060D | 3470*1190*2650 | 600*900 | 25 | 11-12 | 2 |

VK-12065D | 3600*1460*2700 | 650*1200 | 29 | 13-14 | 2.5 |

1

Applications

Mainly used for EPE lamination between the upper and lower layers, instead of traditional hot-air gun and hot-melt adhesive.

2

Operation Principles

The upper EPE layer is moved onto the ironing station for heating by the principal axis, burnt around 3mm and then instantly laminated together with bottom layer, Instead of the tedious manual operation.

3

Performance Advantages

1.Steadily running with multi-axis servo control, imported electronic components and controllers;

2.Easy maintenance;

3.Advanced equipment os, and easy operation;

4.Safer and more reliable.Faster than one station machine, and different thickness and layers could be handled by two work-stations as well as simple irregular EPE products.

Fast & safe Delivery

We support both OEM & ODM packaging. Our normally delivery method are by the sea and road transport.

About the goods

Every item 100% tested before shipped to you.If there is something wrong,pls kindly contact us to deal with that.

About feedback

For this store, your ideas and suggestions are very important. Can you take a minute or two to give us your valuable comments or suggestions? Please thank you in advance.

Company Features1. Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is reliable manufacturer of roll to roll laminator . We have been the market leader for this segment in China for many years.

2. Our products are selling very well. We have built a solid customer base and have completed numerous orders from customers all over the world.

3. The service principle of Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd has always been plastic lamination machine . Check now! Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd upholds the ideas of quality first, sustainable development and constant innovation. Check now! big laminating machine expresses Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's adherence to the 'people-oriented' development concept. Check now! Under the guidance of the vision of EPE foam automation machine , Veinas provides customers with large laminating machine services that meet different requirements. Check now!