[Original] The working process of the foam forming machine The motor of the eps foam building module equipment

by:Veinas

2021-07-21

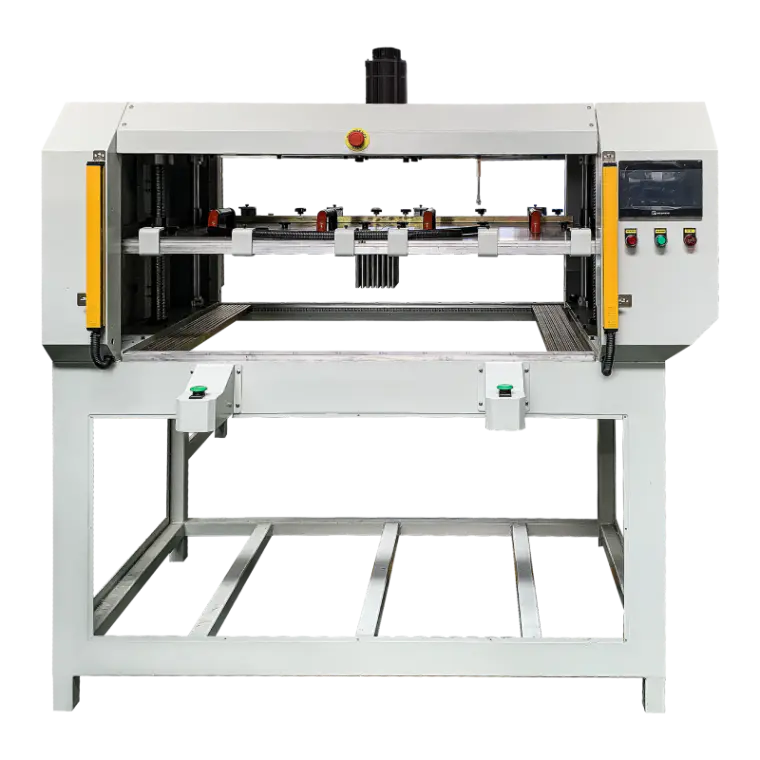

Everyone already knows about the eps foam building module equipment, eps foam building module equipment, manufacturers, manufacturers and other issues, what about the 'work flow of the foam molding machine, the motor of the eps foam building module equipment'? It is estimated that many people are not familiar with it. Today we will get familiar with the experts! 1. The inner template of the forming machine adopts a horizontally adjustable compression system, which can improve the adhesion, porosity, moisture content, thermal conductivity of the plate and increase the flame retardancy of the plate, reduce the probability of plate deformation, reduce the generation of waste, and reduce production costs . 2. The equipment has a built-in surface pressure sensing device, which can accurately sense the pressure between the plate and the inner mold cavity during production, thereby effectively controlling the forming time of the plate, ensuring the yield of the plate and reducing the deformation of the plate. 3. The vacuum system, air pressure, and hydraulic components adopt well-known brand products to ensure the high-quality operation of the equipment. 4. The body of the forming machine is welded with high-quality steel. Through sandblasting and other treatments, the equipment is neatly strengthened and can withstand the expansion force and external impact of high-density plates. 5. The mold cavity adopts a stainless steel template, the steel structure has a reasonable thickness, has a strong anti-corrosion ability, and is easy to clean. The surface is polished and mirrored, which is good for demolding. 6. Adopt low-pressure and large-flow vacuum penetration molding technology to increase output. 7. The control system adopts touch screen and PLC, automatic cycle production, automatic foam detection, and the workflow of the foam forming machine ensures the orderly production of real gold plates. You may be interested in the article: Maintenance of silicon polystyrene EPE foam machine from every detail. The production process of eps foam building module equipment has great energy-saving potential. Taking injection molding machine as an example, the process of injection molding machine is generally divided into locks There are several stages such as mold, injection, melting, pressure holding, cooling, and mold opening. Each stage requires different pressure and flow. For the oil pump motor, the injection molding process is in a changing load state. In the hydraulic system of the fixed pump, the oil pump motor provides a constant flow rate at a constant speed, and the excess hydraulic oil flows back through the overflow valve. This process is called high pressure section. Flow, this backflow will cause energy loss. The use of frequency converters can solve this problem. After adjusting the speed of the oil pump, the oil pump can provide appropriate oil pressure at various stages of injection molding machine production, which greatly reduces energy loss. As early as some end users who used frequency converters in eps foam building module equipment, system integrators provided them with a frequency conversion energy-saving transformation program for eps foam building module equipment, which has achieved remarkable results, so more and more eps foam building module equipment users Renovated their equipment with frequency converter. Is the introduction of the motor and other issues of the eps foam building module equipment helpful to you? If it helps, please continue to pay attention to the introduction of our manufacturers, manufacturers, eps foam building module equipment,! Keywords of this article: Foam molding, sheet equipment, production system

Most places have a few choices when it comes to machine manufacturer automation equipment manufacturer distributors, but it can sometimes be difficult to find the right supplier for your needs. The quality of automation equipment manufacturer is critical to machine manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is one of the best provider in China offering online automation equipment manufacturer consultation and products to boost your machine manufacturer. Visit Veinas Machinery and place your order now.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

Simultaneously being able to offer not only the product but also the service, gives the customer a quality 'one-stop-shop' service.

automation equipment manufacturer are raising the stakes of social marketing, but they also ease the sales process by providing ways for machine manufacturer to effectively interact with customers.

Most places have a few choices when it comes to machine manufacturer automation equipment manufacturer distributors, but it can sometimes be difficult to find the right supplier for your needs. The quality of automation equipment manufacturer is critical to machine manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is one of the best provider in China offering online automation equipment manufacturer consultation and products to boost your machine manufacturer. Visit Veinas Machinery and place your order now.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

Simultaneously being able to offer not only the product but also the service, gives the customer a quality 'one-stop-shop' service.

automation equipment manufacturer are raising the stakes of social marketing, but they also ease the sales process by providing ways for machine manufacturer to effectively interact with customers.

Custom message