[Original] How to use the foam forming machine_The working principle of the foam forming machine

by:Veinas

2021-07-22

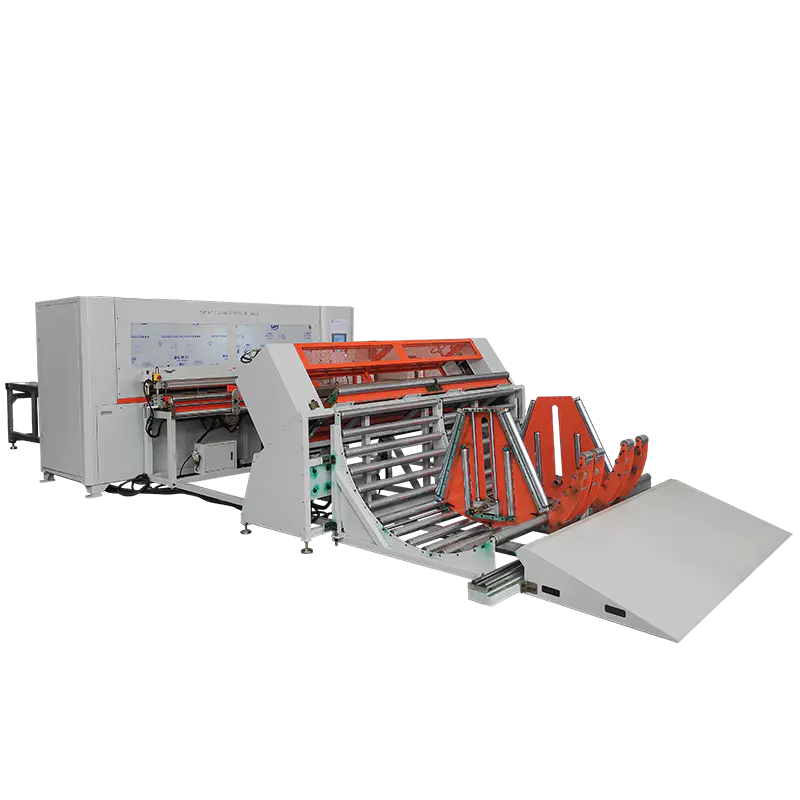

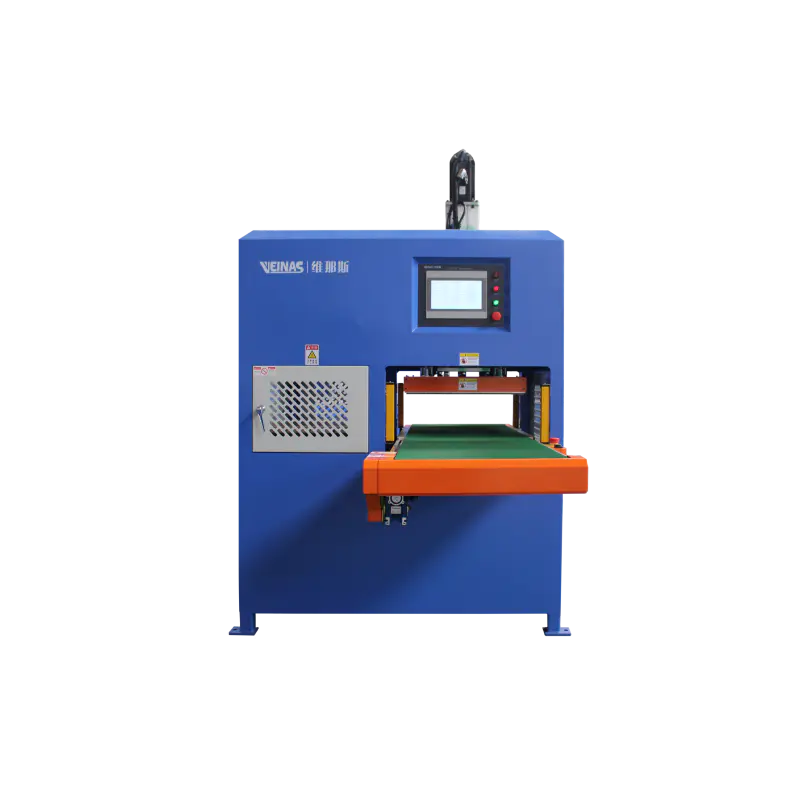

Hebei Changxing Foam Machinery Co., Ltd. is a company specializing in silicon polystyrene EPE foam machine, and its field is also quite prominent. Today we can learn more about the company's details. The working principle of the molding machine and the injection molding machine Syringe is similar. It uses the thrust of screw (or plunger) to inject plasticized plastic in molten state (that is, viscous flow state) into a closed mold cavity, and obtain the product after solidification and shaping. How to use the molding machine: 1. Choose a flat table, put the machine steady, and pull the molding machine feet apart to make the machine panel easy to observe. 2. Insert the plug on the hand-held sensor head into the socket on the panel and tighten it. Pay attention to the positioning gap. 3. Insert one end of the plug of the power cord into the socket on the rear panel of the chassis, and the other end into the power supply socket. Be sure to use a single-phase three-wire power supply. 4. Turn on the 'main power switch' on the back panel of the molding machine, press the 'power switch' button on the panel, and wait for the 'ready' green indicator light to turn on the foam, how to use the foam molding machine to work. Welcome to read: The foam molding machine computer adopts imported PLC computer host chip, plus LCD screen, software fault self-diagnosis system and error correction system, which makes the operation more convenient. Its control program is designed in a fool-style, simple, convenient, and unnecessary. Professional training can start operation. The full hydraulic drive of the foam molding machine has domestic hydraulic frequency modulation technology, which solves the adaptability of the foam molding machine to various materials, improves the compactness of the materials, and shortens the molding cycle. There are two necessary factors for the formation of foam, one is the foaming agent solution, and the other is air. Both are indispensable. Without the blowing agent solution, the liquid film surrounding the gas would not form, and there would be no bubbles. And without gas, only the working principle of the foaming agent forming melting foam forming machine, bubbles can not be formed. In the bubble formation system, the blowing agent solution is the dispersion medium, the gas is the dispersed phase, and the gas is dispersed in the liquid to form bubbles, and then the foam is composed of numerous bubbles. In addition to the important factor of blowing agent performance, the introduction of gas into the blowing agent solution is another important factor. The introduction of gas into the liquid must be completed by the molding machine, that is, the foam molding machine adopts a certain method to introduce the gas into the liquid. 'How to use the foam molding machine' and another article on Benzene Board Machinery will provide some help to everyone. We will carefully prepare more content about Hebei Changxing Foam Machinery Co., Ltd. in the follow-up. If you don't want to miss it, we recommend bookmarking our website. Right!

Maintaining machine manufacturer is not as easy as it may seem. You have to do plenty of important tasks. So cruel is the truth unless you've got a to help you.

As a result, consumers will reward Veinas with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

This is crucial when you need to maintain innovative information in automation equipment manufacturer.

In various different types of machine manufacturer, machine manufacturer automation equipment manufacturer is one of the most commonly used.

Maintaining machine manufacturer is not as easy as it may seem. You have to do plenty of important tasks. So cruel is the truth unless you've got a to help you.

As a result, consumers will reward Veinas with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

This is crucial when you need to maintain innovative information in automation equipment manufacturer.

In various different types of machine manufacturer, machine manufacturer automation equipment manufacturer is one of the most commonly used.

Custom message