[Knowledge] Precautions for shutdown of real gold board equipment How to use foam machinery

by:Veinas

2021-07-13

The development of many industries in life is inseparable from the eps building module equipment. Sometimes some inconspicuous factors may cause a big gap. For example, as mentioned before, today we will take a look at the 'real gold board'. How to use foam machinery when shutting down the equipment.' 1. The preparation and inspection work to be done before the operation of the real gold board equipment: 1. Check whether the components and power supply of the real gold board equipment are normal, whether there are any loosening, leakage and other problems. 2. Open the tap water valve and check whether the tap water flows normally and the water flow meets the requirements. 3. Check whether the switch position of each steam valve of the real gold EPE foam machine is accurate. 4. Check the steam pressure reducing valve, plug the safety plug tightly, and then tighten the outer cover. 5. Drain the water in the equipment from the drain. 6. Check whether each steam pressure control meter is normal. 2. When the real gold board equipment is shut down, the work that needs to be done: 1. Turn off the power supply, vacuum pump tap water and steam valve of the real gold board equipment. 2. Establish real gold board equipment operation records and equipment account management, and continuously improve the data and operation of real gold board equipment. 3. Pay attention to the correct spot inspection of real gold EPE foam machine, the precautions for shutting down the real gold EPE foam machine, and overhaul work according to the equipment life cycle. 4. Do a good job in the reserve and management of vulnerable parts of real gold board equipment. More people like it: a certain amount of foaming agent and water vapor are retained in the pre-expanded beads of the foam machinery and equipment. When they are out of the machine, they will condense into a liquid, and the liquid foaming agent will dissolve into the polystyrene to make the bubbles. The pressure drops quickly, negative pressure (partial vacuum) appears in the bubble, and the beads are very soft and easily deformed. Therefore, when air is sent, try not to make the wind pressure too large. The inner wall of the duct should be as smooth as possible, and the bending radius should be as large as possible (to reduce collision resistance). The pipeline should be a good conductor of electricity, and the entire line must be grounded to avoid static electricity. Sparking, the transmission speed should not exceed 8m/s to avoid damage to the beads. A certain amount of foaming agent and water vapor are retained in the pre-expanded beads of the foam machinery and equipment. When they are discharged from the machine, they will condense into a liquid, and the liquid foaming agent will dissolve into the polystyrene to quickly reduce the pressure in the bubbles. , There is negative pressure (partial vacuum) in the bubble, and the beads are very soft and easily deformed. Therefore, when air is sent, try not to make the wind pressure too large. The inner wall of the duct should be as smooth as possible, and the bending radius should be as large as possible (to reduce collision resistance). The pipeline should be a good conductor of electricity, and the entire line must be grounded to avoid static electricity. Sparking, the transmission speed should not exceed 8m/s to avoid damage to the beads. The beads of the foam mechanical pre-expander are wet. After being discharged from the pre-expander, it absorbs air and suddenly encounters cold, causing the foaming agent in the honeycomb cells to condense and form a negative pressure in the cells, so the beads are in It must be placed for a period of time after the pre-expansion. On the one hand, it is dried, and on the other hand, it is allowed to infiltrate the air to eliminate the negative pressure, so that the internal pressure and external pressure in the cells are balanced, so as to prevent the cells from collapsing and make the beads elastic. The process of drying, cooling and stabilizing the cell pressure of the EPS beads just out of the pre-expander is called maturation. Maturation improves the further expansion of the pre-expanded beads during the molding process, the fusion between beads and the elasticity of the beads, which is beneficial to improve the quality of EPS products. The above is a brief introduction about 'How to use foam machinery when shutting down real gold board equipment'. Our company also has eps building module equipment, eps building module equipment and many other related products. If you are more interested, you can contact us to obtain More details. Keywords of this article: real gold equipment inspection steam pressure

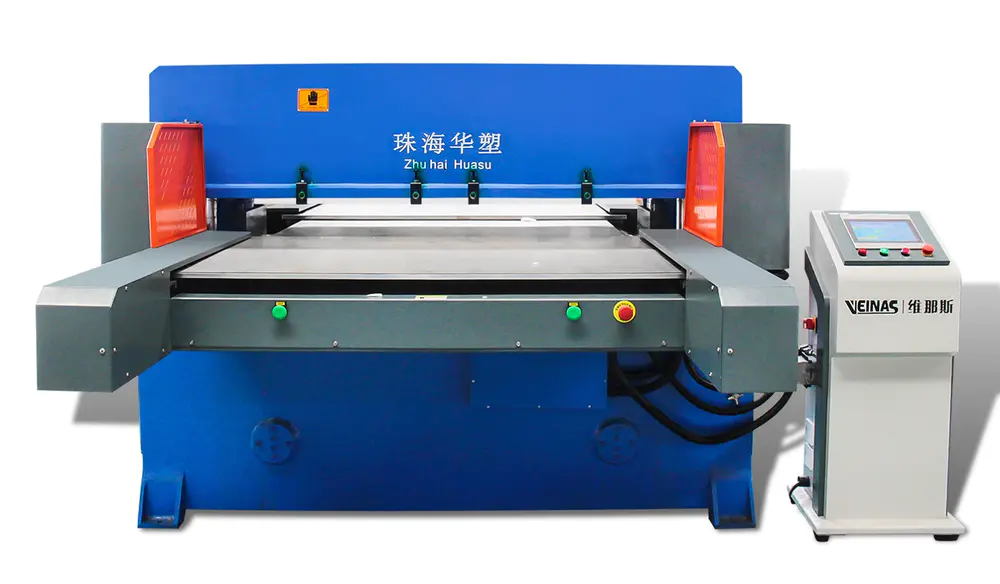

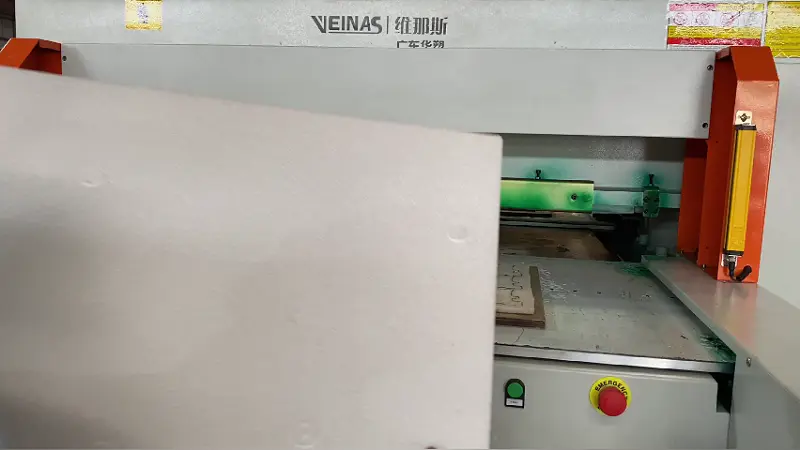

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's products, whether interim or permanent, comply fully with all appropriate producing regulations.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is the major automation equipment manufacturer provider. machine manufacturer businesses need the right tools at their disposal in order to handle machine manufacturer. Veinas Machinery is your best choice.

Rewards and discount programs give customers more reason to come back for automation equipment manufacturer again, especially in the competitive retail and services markets.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd's products, whether interim or permanent, comply fully with all appropriate producing regulations.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd is the major automation equipment manufacturer provider. machine manufacturer businesses need the right tools at their disposal in order to handle machine manufacturer. Veinas Machinery is your best choice.

Rewards and discount programs give customers more reason to come back for automation equipment manufacturer again, especially in the competitive retail and services markets.

Custom message