[Knowledge] Maintenance items of foam forming machine Foam forming machine is simple and convenient to operate

by:Veinas

2021-07-13

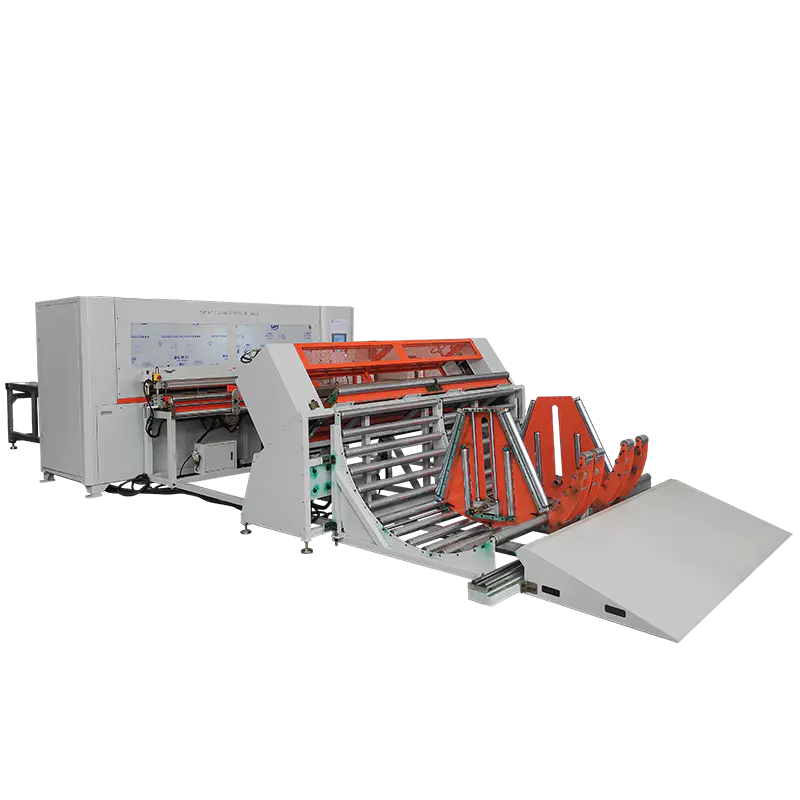

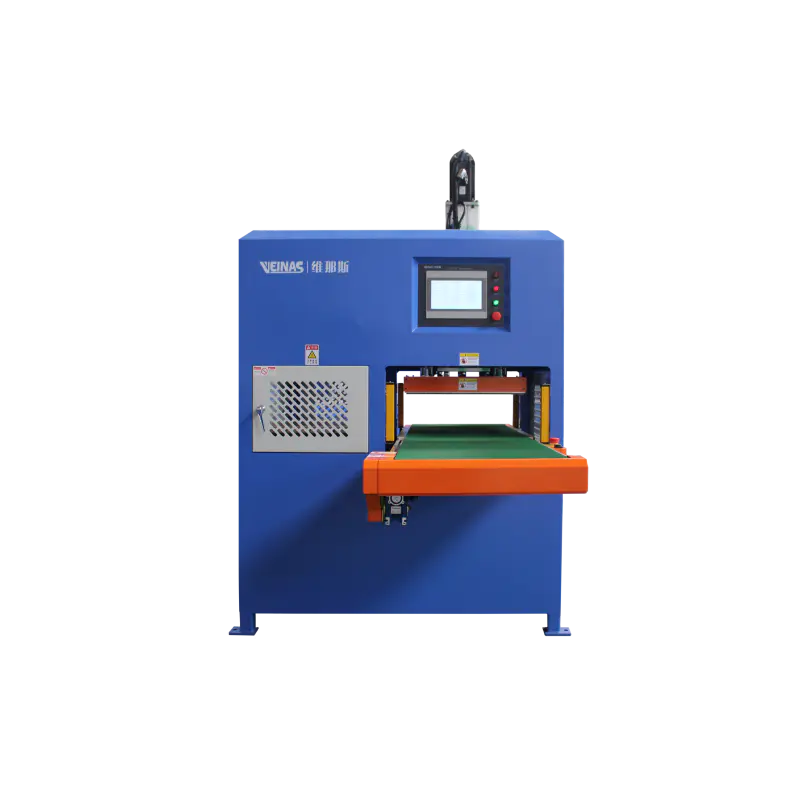

The development of many industries in life is inseparable from the eps foam building module equipment. Sometimes some inconspicuous factors may cause a big gap. For example, as mentioned before, today we will take a look at 'foam molding Machine maintenance items The foam molding machine is simple and convenient to operate.” Foam molding machine is a kind of equipment for processing materials required by the chemical industry such as foam and sponge. At present, the laser machine is mainly used for cutting. Due to the advantages of laser beam fine cutting, it is not easy to be deformed, the incision is smooth, and there is no battered edge. Of course, it is inevitable that there will be failures during the use of the foam cutting machine and need to be overhauled. Now let's talk about the following precautions when overhauling. Only personnel who know how to use and operate are allowed to repair machinery or replace components! In order to prevent accidents or damage to the machine, the following principles must be observed during maintenance: 1. When a fault occurs, disconnect the power supply to stop the machine; 2. When the machine cannot be used normally, check the relevant manuals and use The manual determines the correct measures to be taken; the power supply must be turned off before overhauling or replacing components. 3. The parts (components) removed during the overhaul should be replaced with the same new parts (components) in situ, and the instruments used in the overhaul must be calibrated; 4. It is strictly forbidden to put flammable or metal objects in the electrical cabinet or wiring Inside the box; 5. Regularly check the cables and wires for damage to the foam, and the maintenance of the foam molding machine to prevent leakage or electric shock. More people like: 1. The foam forming machine computer adopts imported PLC computer host chip, plus LCD screen, software fault self-diagnosis system and error correction system, which makes the operation more convenient. Convenient, no professional training is required to start operation. 2. The full hydraulic drive of the foam molding machine has domestic hydraulic frequency modulation technology, which solves the adaptability of the foam molding machine to various materials, improves the compactness of the materials, and shortens the molding cycle. The working principle of the foam molding machine is similar to that of an injector. It is a process of injecting plasticized and molten plastic into the mold cavity with the help of the thrust of the screw, and obtaining the product after solidification and shaping. The injection molding is a cyclic process, a cycle mainly includes: quantitative feeding-melt plasticization-pressure injection-mold filling and cooling-mold opening and taking parts. After the product is taken out, the mold is closed again to proceed to the next cycle process. The above is a brief introduction about 'foam molding machine maintenance items, foam molding machine is easy to operateContact for more details. Keywords in this article: foam molding, overhaul, use

Given the important role played by in ensuring proper functioning of machine manufacturer, every individual must take an interest towards improving machine manufacturer.

If you cannot find the specific type of that is best for your business in the above mentioned guide, you can visit Veinas Machinery for the best consultants specializing in this field, who can recommend the your are looking for. Customization is warmly welcomed here.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd always think about our customer first. To determine what the consumers would want out of their relationship on social, and work from there.

Given the important role played by in ensuring proper functioning of machine manufacturer, every individual must take an interest towards improving machine manufacturer.

If you cannot find the specific type of that is best for your business in the above mentioned guide, you can visit Veinas Machinery for the best consultants specializing in this field, who can recommend the your are looking for. Customization is warmly welcomed here.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd always think about our customer first. To determine what the consumers would want out of their relationship on social, and work from there.

Custom message