[Inventory] Introduction to the configuration of the foam cutting machine How does the foam forming machine work?

by:Veinas

2021-07-14

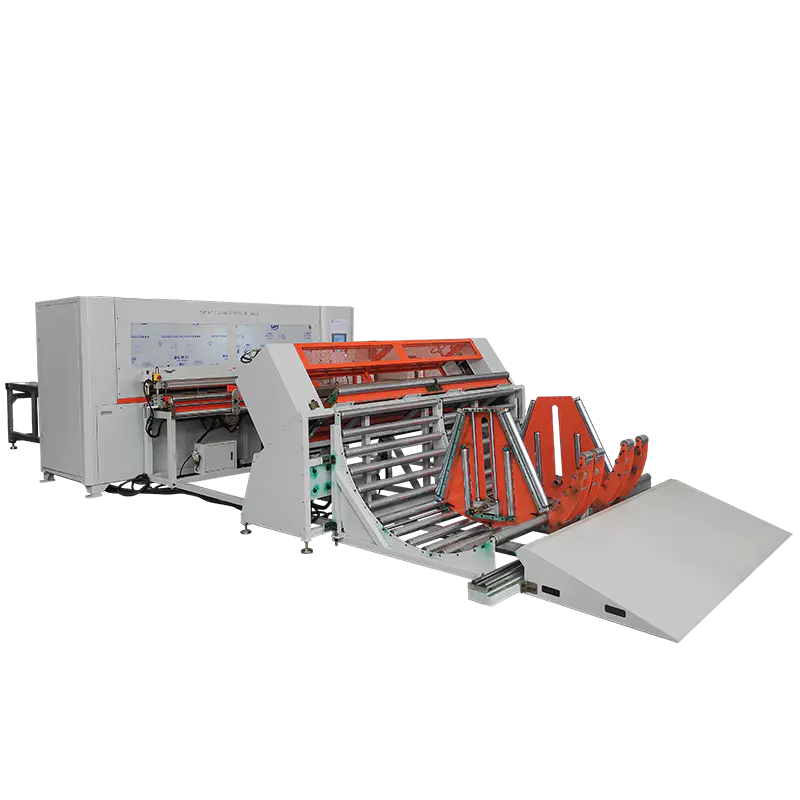

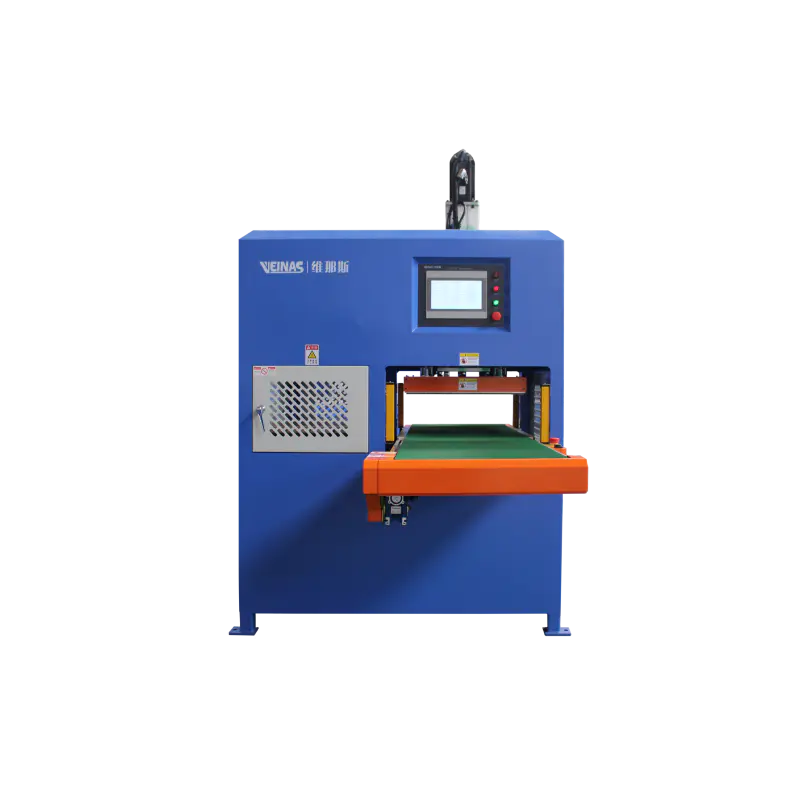

Do you know 'Introduction to the configuration of the foam cutting machine and how does the foam forming machine work'? Today, Hebei Xinsu Foam Machinery will introduce you to this aspect. I hope that through the introduction of this article, you can have a certain understanding and understanding of how the foam forming machine works. Let’s take a look at it together. Related introduction: The structural characteristics of foam cutting machinery are as follows: 1, equipped with a movable cutting and adjusting device. In order to ensure the size and accuracy of the cutting material, the machine is equipped with a digital display ruler. 2. The movable worktable adopts the suction method of negative pressure, and the cut foam can be fixed and not shifted randomly. 3. When the operation is stopped, it is equipped with manual and automatic devices. 4. The red brake button of the foam cutting machine is used for manual braking. When the start button is pressed, the button becomes invalid. When the brake electromagnets are attracted to each other, press the start button foam again. The configuration of the foam cutting machine introduces the brake electromagnet to release immediately. More attention: The working principle of the molding machine is similar to that of the syringe used for injection. It uses the thrust of the screw (or plunger) to inject the plasticized plastic in the molten state (that is, the viscous flow state) into the closed one. In the mold cavity, the process of obtaining the product after curing and shaping. How to use the forming machine: 1. Choose a flat table and stabilize the machine. The legs of the forming machine can be pulled apart to make the machine panel easy to observe. 2. Insert the plug on the hand-held sensor head into the socket on the panel and tighten it. Pay attention to the positioning gap. 3. Insert one end of the plug of the power cord into the socket on the rear panel of the chassis, and the other end into the power supply socket. Be sure to use a single-phase three-wire power supply. 4. Turn on the 'main power switch' on the back panel of the molding machine, press the 'power switch' button on the panel, and wait for the 'ready' green indicator light to turn on, the machine can work. The points introduced above are about 'the configuration of the foam cutting machine introduces how the foam forming machine works'. I believe that after reading the introduction of this article, I will have my own understanding of this aspect, and I will focus on the foam forming machine in the future. How it works can also be solved very well. Here, we recommend that you learn more about manufacturers, manufacturers, foam incubator equipment, etc., and hope to help you! Keywords of this article: Foam Cutting Machine Power Supply Machine Brake Button Forming

automation equipment manufacturer is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

We humbly ask you to use automation equipment manufacturer and we guarantee that you would be in a great delight with using the product.

To offer abundant options of product is an important factor to a company, such as automation equipment manufacturermachine manufacturer to afford high-quality products for customers.

automation equipment manufacturer is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

We humbly ask you to use automation equipment manufacturer and we guarantee that you would be in a great delight with using the product.

To offer abundant options of product is an important factor to a company, such as automation equipment manufacturermachine manufacturer to afford high-quality products for customers.

Custom message