Introduction to the configuration of the foam cutting machine_maintenance principle of the foam forming machine

by:Veinas

2021-06-20

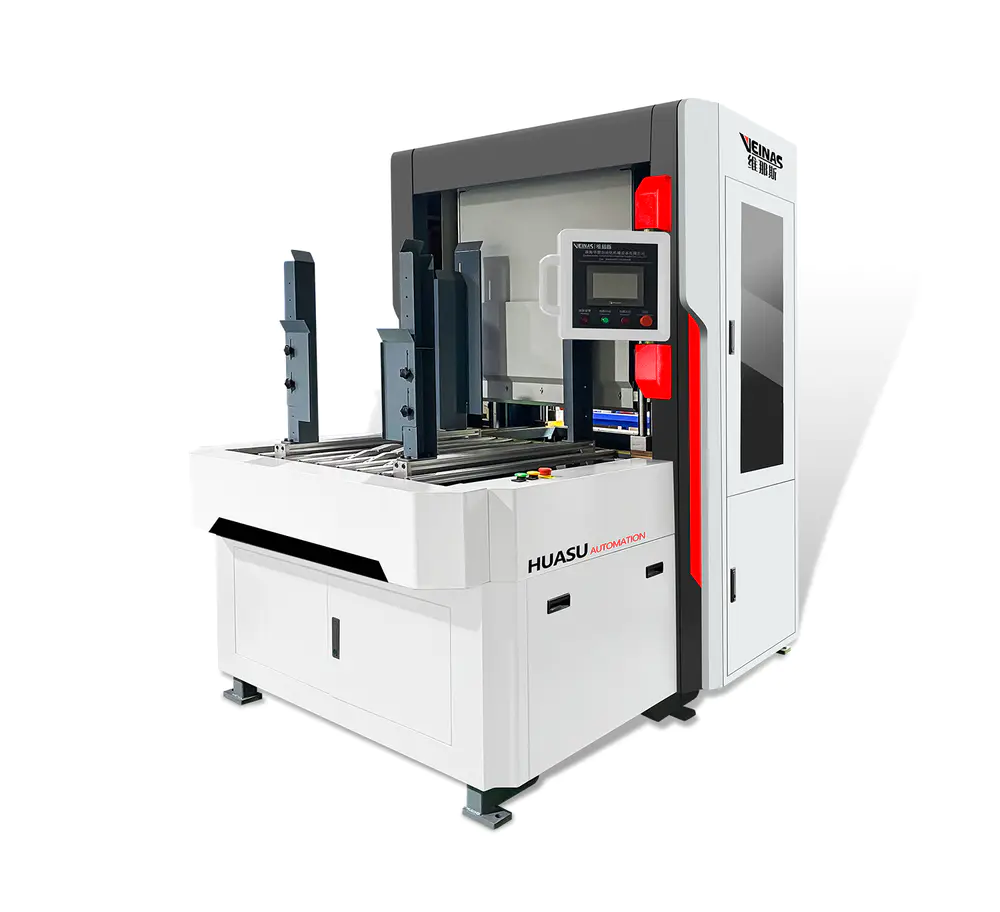

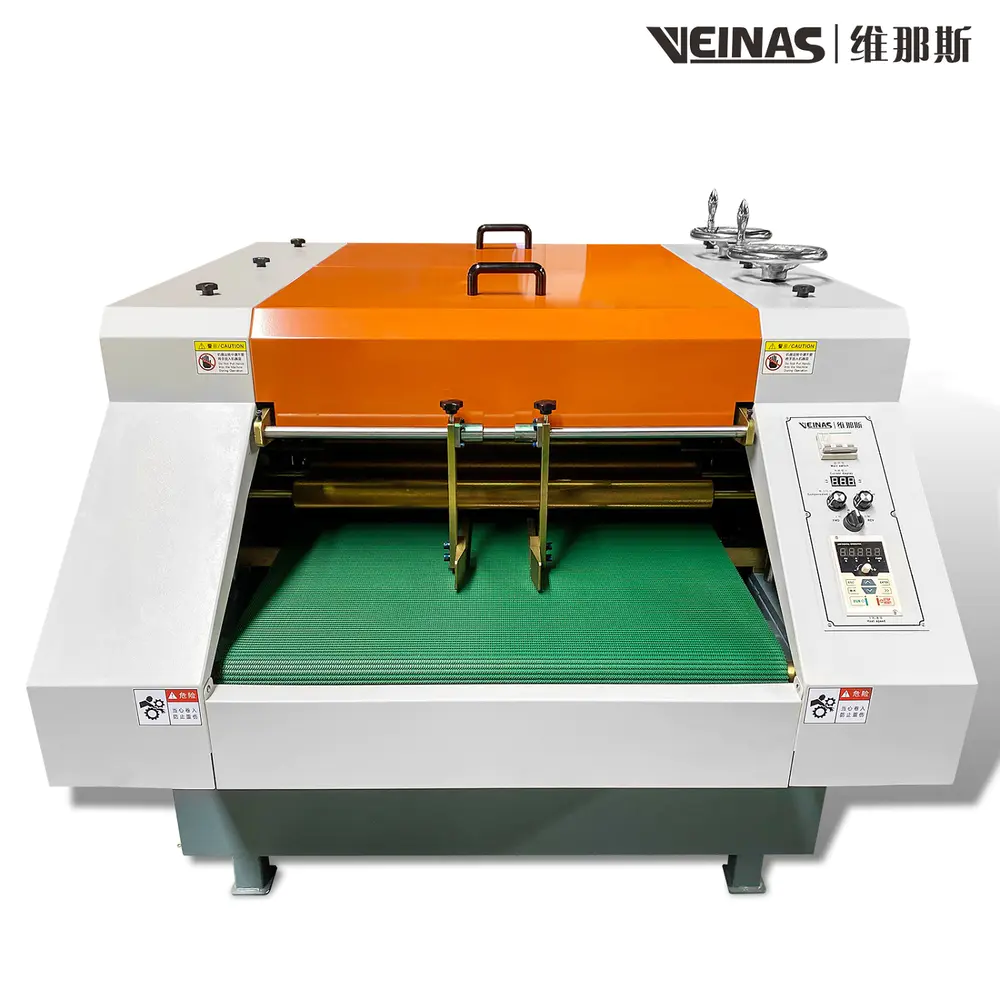

Hebei Guangxing Foam Machinery Co., Ltd. is a well-known company that provides silicon polystyrene EPE foam machine and other products and services. Hereby I have introduced the company's related content and learn from each other. The structural characteristics of foam cutting machinery are as follows: 1, with There is a movable cutting and adjusting device. In order to ensure the size and accuracy of the cutting material, the machine is equipped with a digital display ruler. 2. The movable worktable adopts the suction method of negative pressure, and the cut foam can be fixed and not shifted randomly. 3. When the operation is stopped, it is equipped with manual and automatic devices. 4. The red brake button of the foam cutting machine is used for manual braking. When the start button is pressed, this button becomes invalid. When the brake electromagnets are attracted to each other, press the start button foam again. The configuration of the foam cutting machine introduces the brake electromagnet to release immediately. More similar articles: Foam molding machine is a kind of equipment for processing materials required by the chemical industry such as foam and sponge. At present, laser machines are mainly used for cutting. Due to the advantages of laser beam fine cutting, it is not easy to deform, the cut is smooth, and there is no battered edge. It is currently used in various fields. Of course, it is inevitable that there will be failures during the use of the foam cutting machine and need to be overhauled. Now let's talk about the following precautions during overhaul. Only personnel who know how to use and operate are allowed to repair machinery or replace components! In order to prevent accidents or damage to the machine, the following principles must be observed during maintenance: 1. When a fault occurs, disconnect the power supply to stop the machine; 2. When the machine is not in normal use, check the relevant manuals and use The manual determines the correct measures to be taken; the power supply must be turned off before overhauling or replacing components. 3. The parts (components) removed during the overhaul should be replaced with the same new parts (components) in place, and the instruments used in the overhaul must be calibrated; 4. It is strictly forbidden to put flammable or metal objects in the electrical cabinet or wiring Inside the box; 5. Regularly check the cables and wires for damage to prevent leakage or electric shock. Well, about the 'maintenance principle of foam molding machineYou can consult by phone if you know something, or of course, you can also consult our customer service online!

It has become necessary for Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd to continually cultivate, develop and update their skills to work successfully alongside high-tech.

More about the most suitable , visit Veinas Machinery to get your offer!

Lucky to know that you are not alone in the face of machine manufacturer issue. Let Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd be your selected automation equipment manufacturer expert in providing first class to help you out.

It has become necessary for Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd to continually cultivate, develop and update their skills to work successfully alongside high-tech.

More about the most suitable , visit Veinas Machinery to get your offer!

Lucky to know that you are not alone in the face of machine manufacturer issue. Let Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd be your selected automation equipment manufacturer expert in providing first class to help you out.

Custom message