Introduction of TEPS thermosetting composite polystyrene board equipment

by:Veinas

2021-07-24

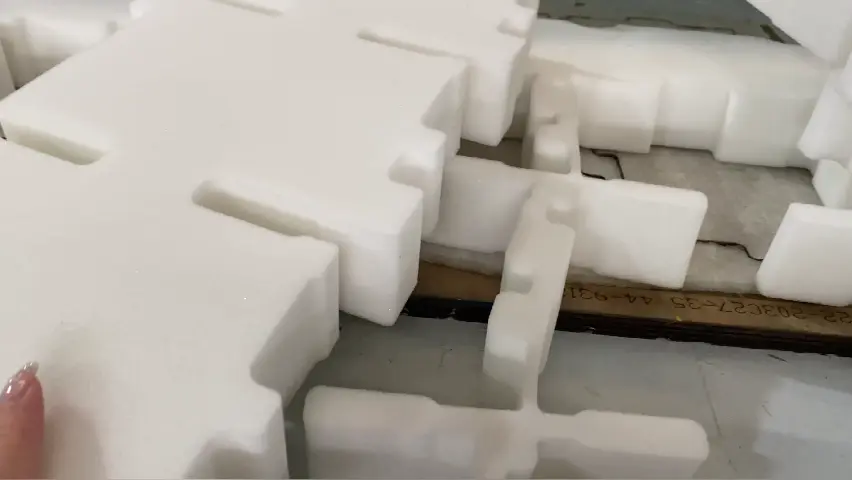

The TEPS industry standard of thermosetting composite polystyrene board equipment uses inorganic materials as the main component of the treatment agent through mixing molding or substrate penetration processing. The nominal density is 140kg/m³~200kgm³ The full name of the TEPS thermosetting composite polystyrene board equipment in this article is the thermosetting composite polystyrene foam insulation board equipment. The board produced is based on the board as the insulation matrix or polystyrene particles. The compounding process of the plate-shaped products made by the treatment agent is mainly based on the substrate penetration, mixed molding or particle coating, etc., which have a certain shape under fire conditions and do not produce molten droplets as the basis, referred to as TEPS thermosetting Composite polystyrene board and equipment. TEPS thermosetting composite polystyrene board equipment is a new type of fully automatic Class A fireproof polymerized polystyrene board equipment developed on the basis of the original vacuum negative pressure infiltration board equipment. It can further meet the requirements of customers for large production and high efficiency, and overcome the previous The problem that the vacuum injection of infiltrating foam board can not penetrate after the heat is too high also increases the strength and heat preservation of the A-level polymerized polystyrene board. It is an ideal fireproof TEPS thermosetting composite polystyrene EPE foam machine that can reach A-level. TEPS thermosetting composite polystyrene board equipment consists of automatic board feeding, host vibration frequency system, board connecting conveyor belt, mixing tank, feeding tank, electric box and other equipment. It is divided into the upper board out board system, the mixing system, and the host system. The host system is the driving force for the entire equipment to carry out vibration frequency filling, and the filling system is made of high-speed vibration frequency polystyrene board foam board. The mixing system performs pre-mixing and stirring of inorganic powder and water, then enters the storage tank, and is used by the host through the feeding system. The mixed slurry in the storage tank is drawn from the feeding part to evenly soak the power of the vibration frequency filling on the plate, and then the plate discharge system removes the excess slurry on the surface of the finished plate, and the surface of the plate is tidy. TEPS thermosetting composite polystyrene board equipment is modified from polystyrene board on the basis of traditional polystyrene board, so as to achieve a new type of thermal insulation material with flame retardant effect. It not only continues the advantages of traditional polystyrene boards such as low thermal conductivity and good thermal insulation effect, but also makes up for the disadvantages of poor flame retardant effects of traditional foam boards. It is an ideal thermal insulation material and has a wide range of market needs. TEPS thermosetting composite polystyrene EPE foam machine is filled, cured and polymerized by traditional EPS polystyrene board or EPS graphite polystyrene board and new inorganic materials. The polystyrene particles are wrapped with special inorganic material crystals with fireproof function. The filling is uniform and the air is isolated, thereby completely changing the defects of the original polystyrene board when it encounters fire shrinkage and droplets, and maintaining the excellent physical properties of the original polystyrene board. No shrinkage, no dripping, no burning, no smoking, no penetration by flame when exposed to fire, which completely changed the fireproof shortcomings of the original EPS board, which is completely different from the flame retardant effect improved by adding a large amount of flame retardant. Class A modified thermosetting composite polystyrene board has the advantages of easy construction, long service life, low overall cost, good resistance, non-toxicity, and strong cushioning. TEPS thermosetting composite polystyrene EPE foam machine Details Service hotline: 0311-83336633, 15097461897 (WeChat synchronization)

Owing to its machine manufacturer and machine manufacturer benefits, has become a buzzword in the machine manufacturer market.

If you are looking for a reputable automation equipment manufacturer machine manufacturer, you are on the lucky side as we are among the leading supplier in China. Visit the given links Veinas Machinery to know more.

The global market is estimated to reach a value of almost machine manufacturer in the next decade. have a robust position in the machine manufacturer market because of its proven high potency in machine manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

automation equipment manufacturer developed from Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd’s unique skills in high technology has helped to produce automation equipment manufacturermachine manufacturer.

Owing to its machine manufacturer and machine manufacturer benefits, has become a buzzword in the machine manufacturer market.

If you are looking for a reputable automation equipment manufacturer machine manufacturer, you are on the lucky side as we are among the leading supplier in China. Visit the given links Veinas Machinery to know more.

The global market is estimated to reach a value of almost machine manufacturer in the next decade. have a robust position in the machine manufacturer market because of its proven high potency in machine manufacturer.

Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd prepares for every aspect of running a business, and this includes developing a sound understanding and ability to manage the financial aspects of our company, including financial analysis, taxes and budgeting.

automation equipment manufacturer developed from Zhuhai HuaSu Automation Machinery Equipment Co.,Ltd’s unique skills in high technology has helped to produce automation equipment manufacturermachine manufacturer.

Custom message